-

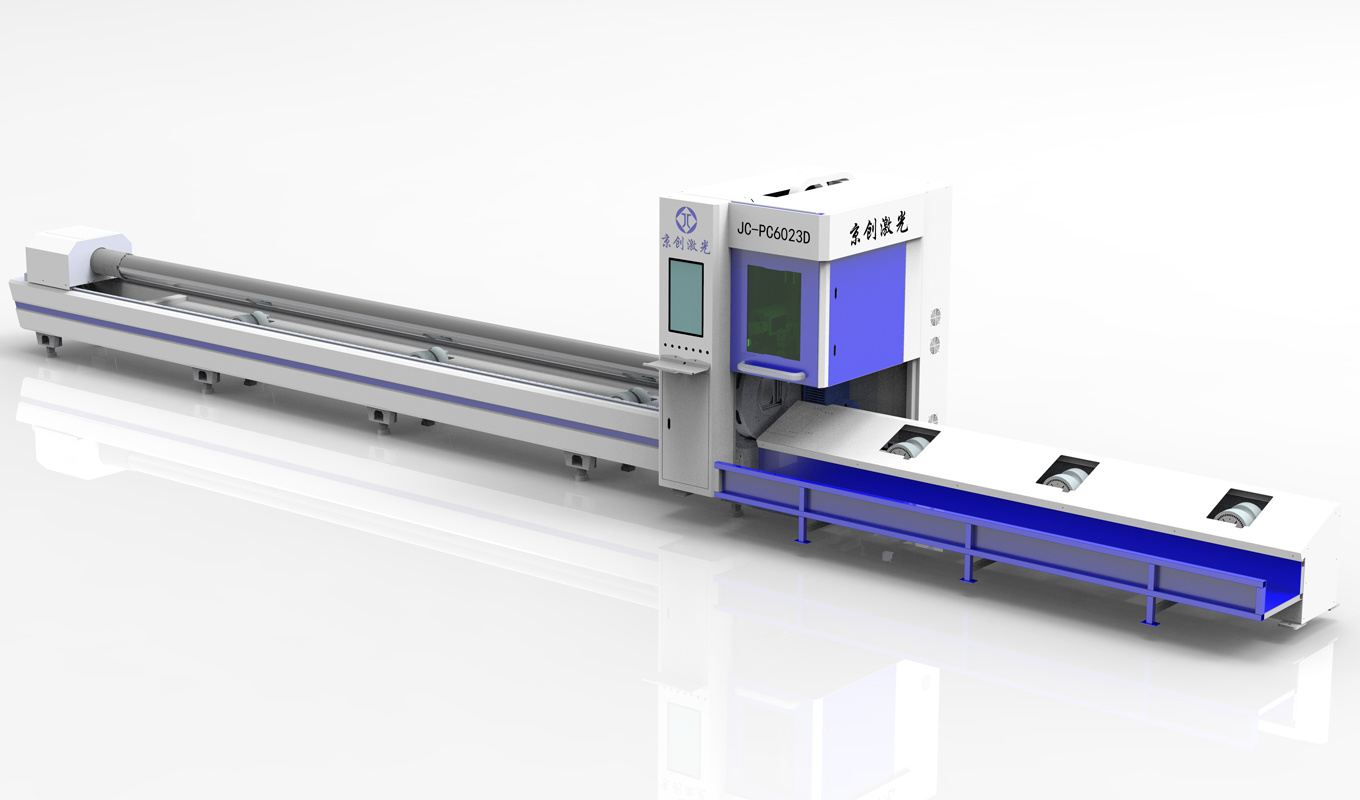

Tube Laser Cutting Machine

Cutting and Slotting any shape Iron Pipe

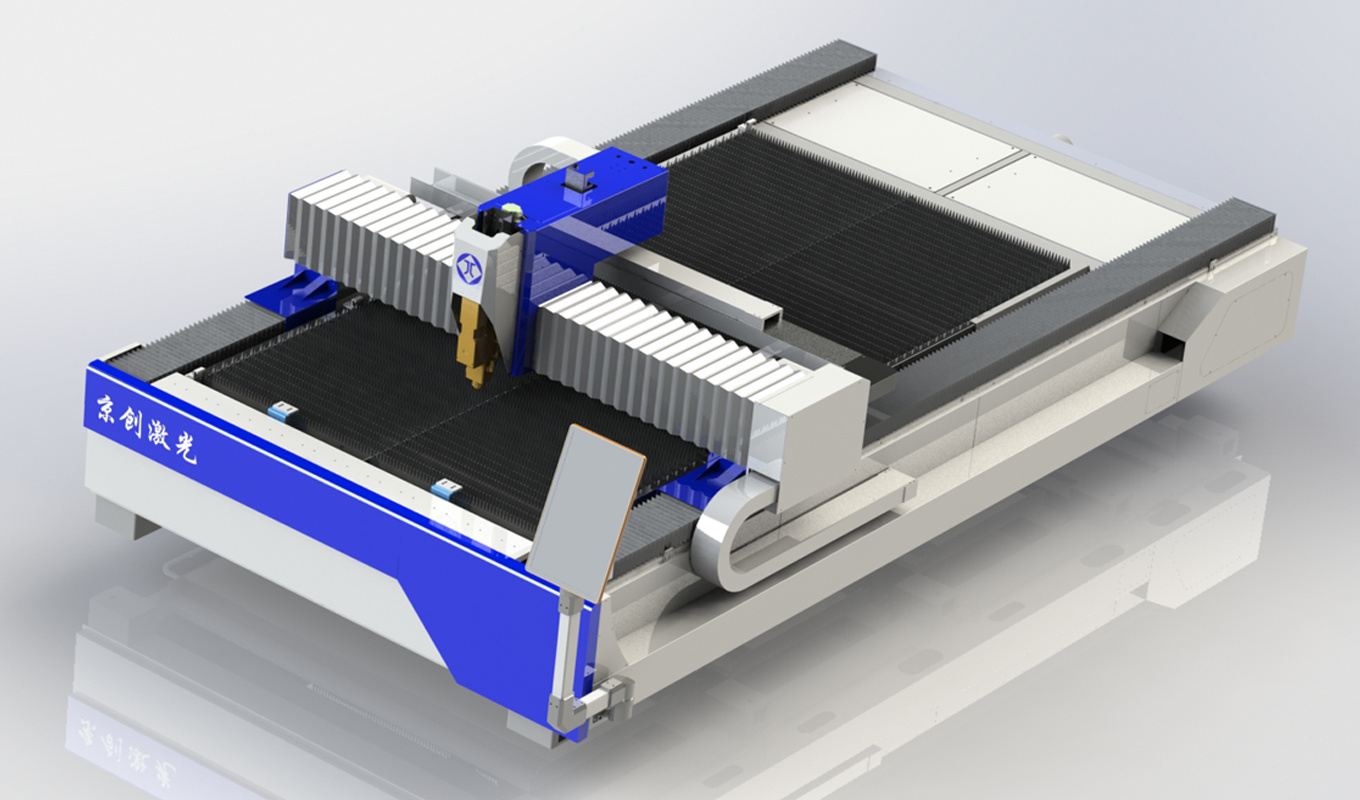

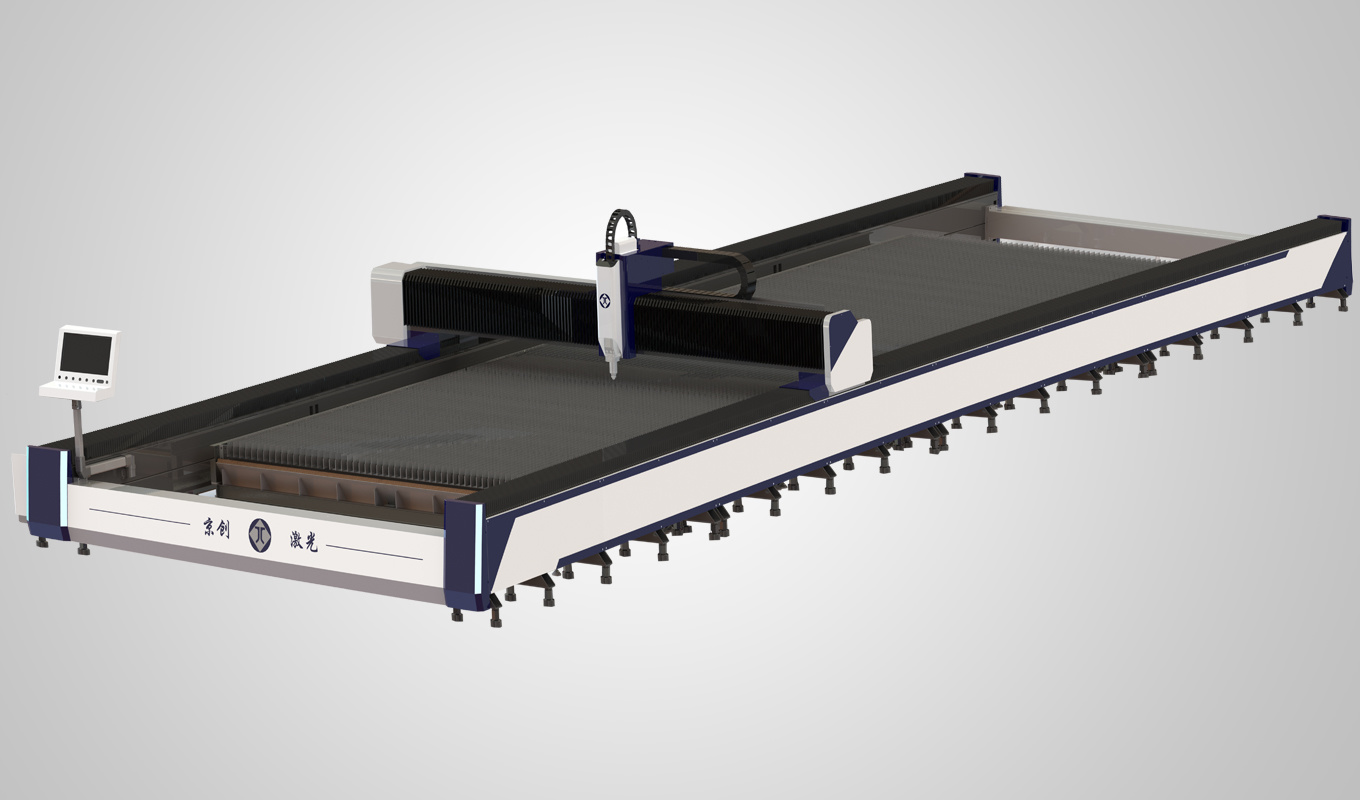

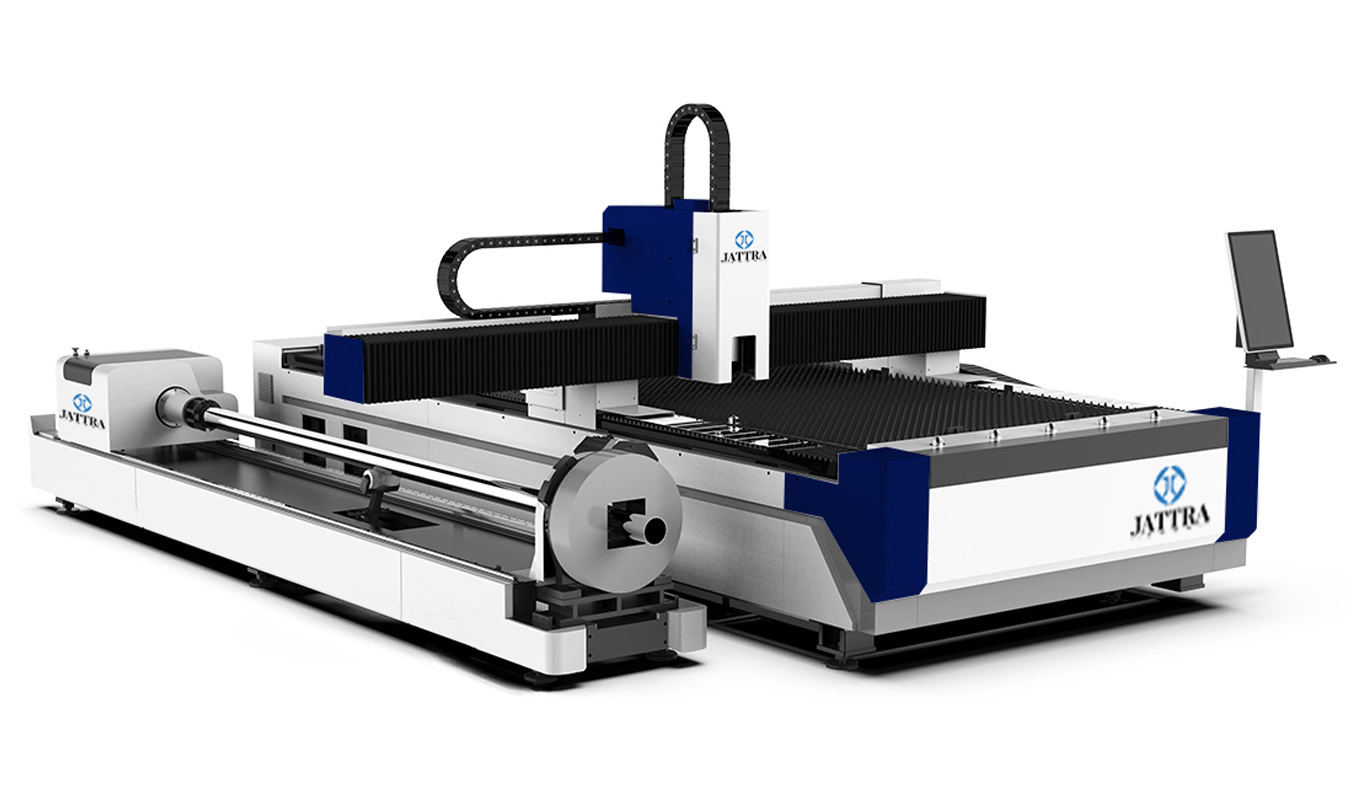

Tube and Sheet 2-in-1 laser cutter

One machine for two uses, European quality

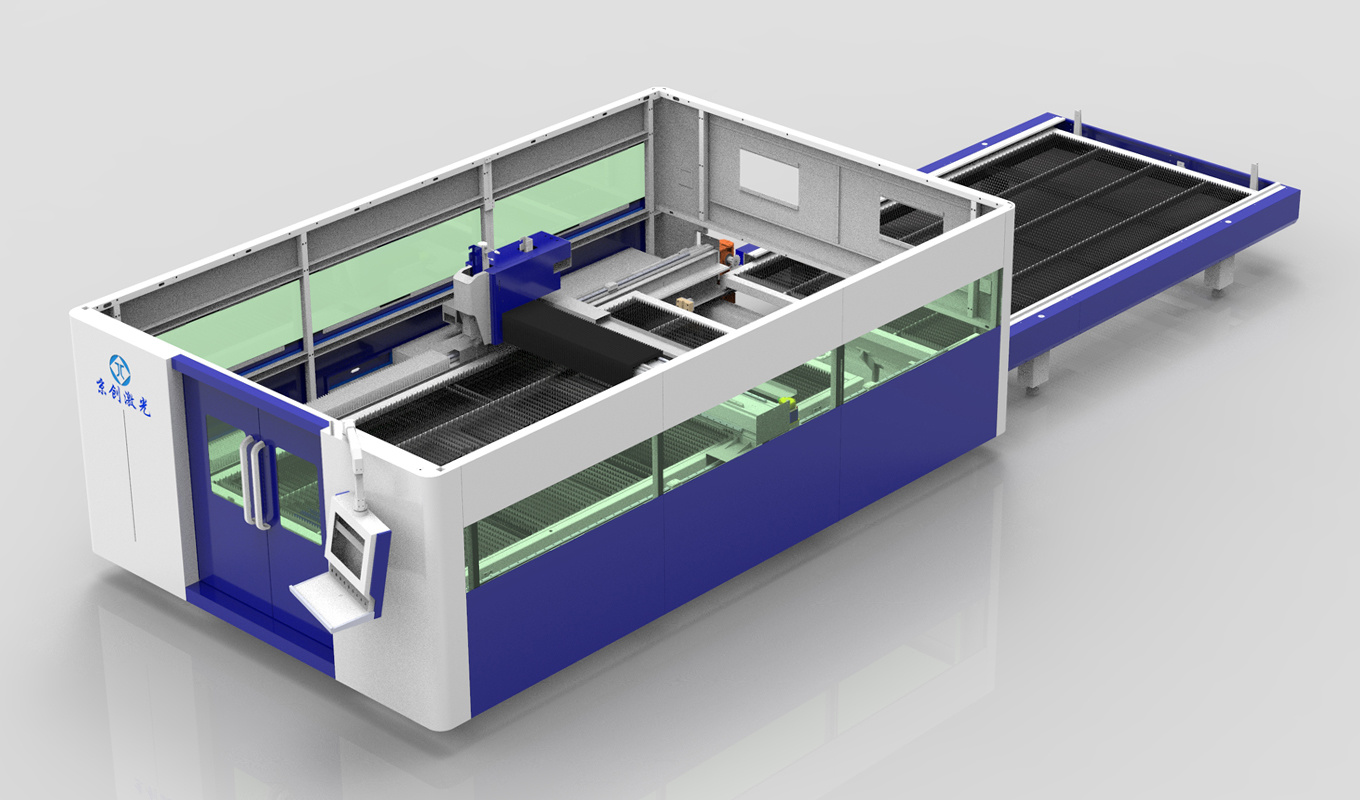

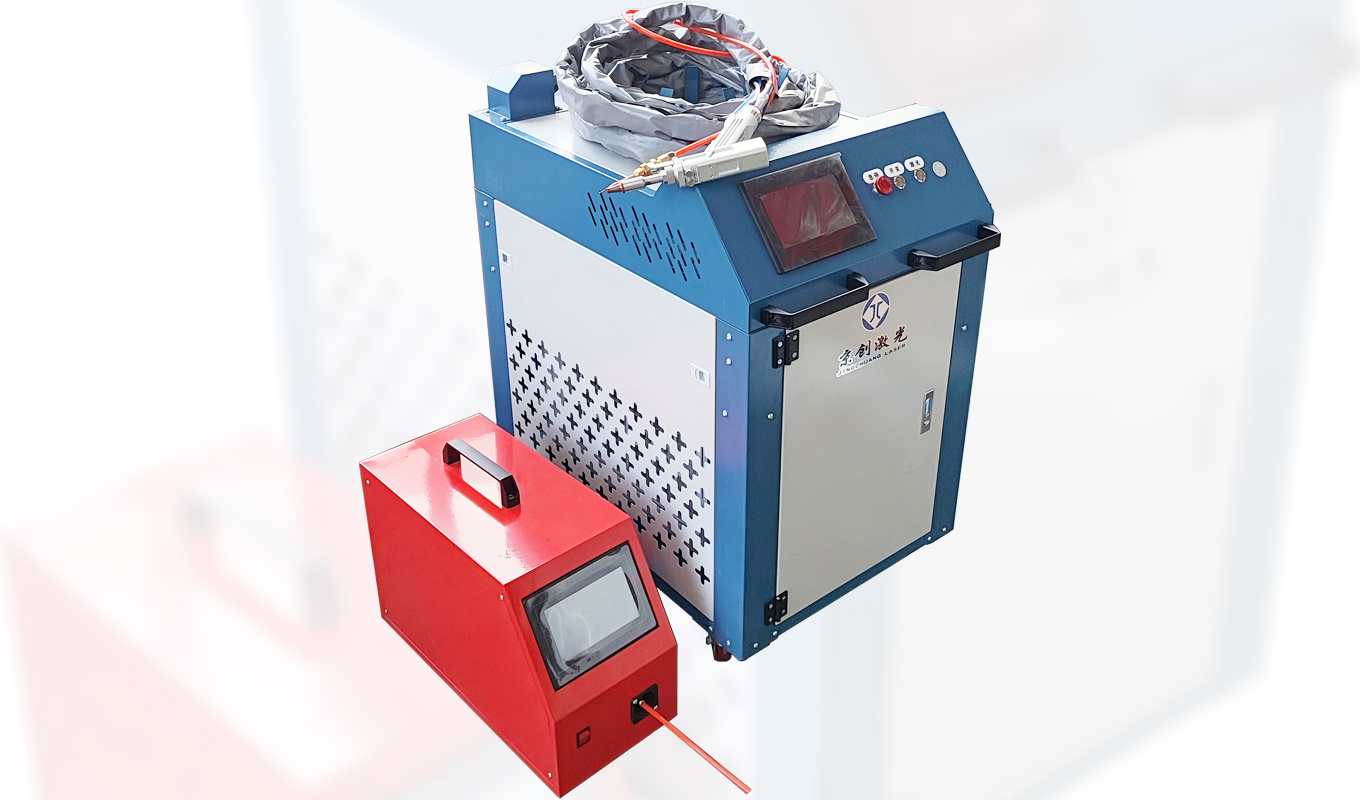

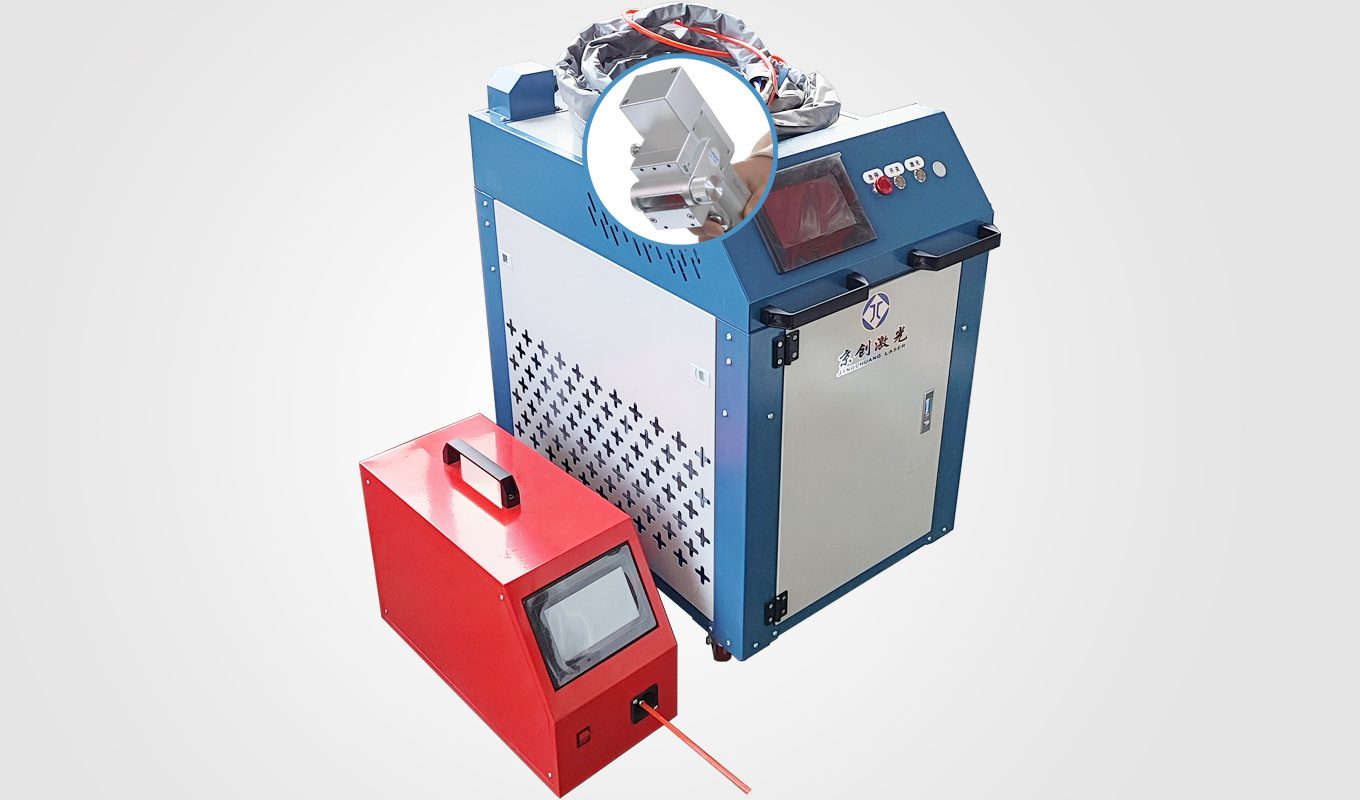

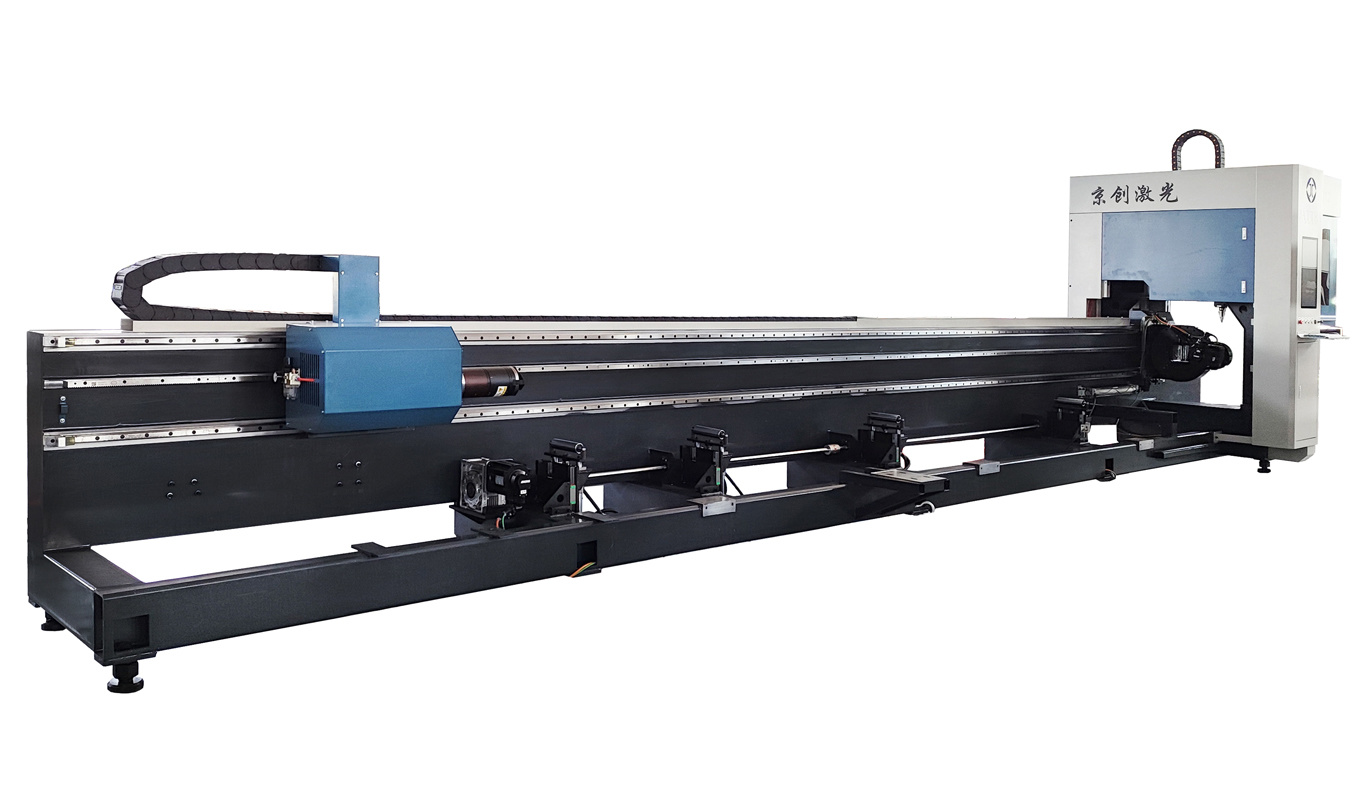

Side hanging Tube laser cutting machine

Side hanging Type tube laser cutter

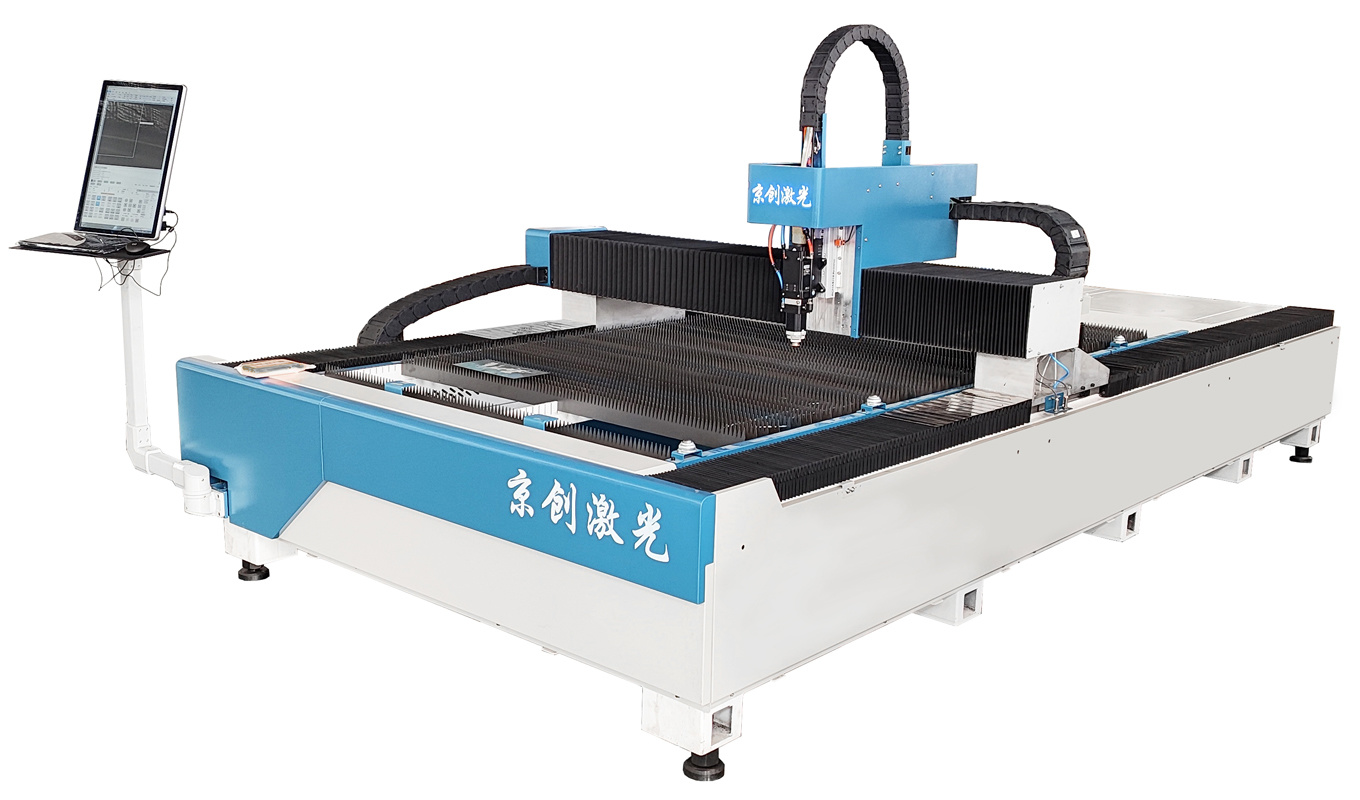

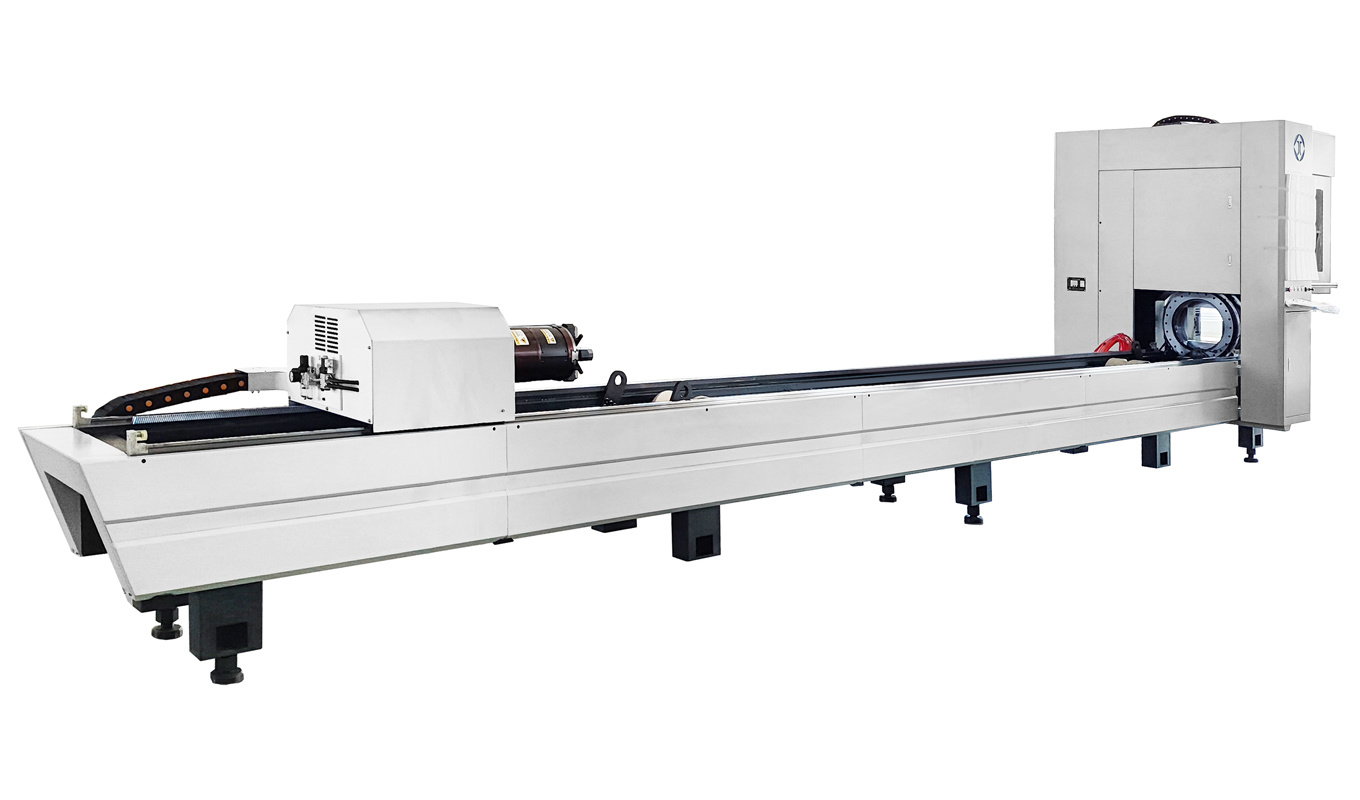

Horizontal Tube laser cutting machine

Horizontal type Tube laser cutting machine.

NEWS CENTER

JINGCHUANG LASER

27

2025

-

08

How to choose auxiliary gas for a laser cutting machine?

How to choose auxiliary gas for a laser cutting machine?

Laser cutting machines commonly use three types of assist gases: oxygen, nitrogen, and compress air. Each has distinct differences in cost, material compatibility, and cut quality. Here’s a detailed breakdown:

1. Gas Characteristics Comparison

-

Oxygen

- Function: Acts as an oxidizer, enhancing cutting speed through combustion, ideal for thick carbon steel.

- Effect: Produces a bright or matte finish, but oxidation may darken the cut edge; positive focus improves cut quality, while negative focus increases speed.

- Cost: Moderate—higher than air but lower than nitrogen.

-

Nitrogen

- Function: Creates an inert shielding gas, preventing oxidation, suitable for stainless steel, aluminum, and other high-precision materials.

- Effect: Delivers a shiny, oxidation-free cut edge, but slower cutting speed; thick materials may develop burrs.

- Cost: Higher, with purity requirements (fewer impurities improve cut quality).

-

Air

- Function: A cost-effective option for materials with lower edge quality requirements (e.g., stainless steel, aluminum).

- Effect: Fastest cutting speed but may result in yellow or darkened edges; long-term use may increase machine maintenance costs.

- Cost: Lowest—only electricity and compressor costs.

2. Material-Specific Recommendations

- Carbon Steel: Oxygen (preferred for thick sheets); thin sheets can use nitrogen or air.

- Stainless Steel: Nitrogen (for a shiny edge) or air (for speed).

- Aluminum/Copper: Nitrogen reduces oxidation; air improves efficiency.

- Titanium Alloy: Air is the most economical; argon (inert gas) preserves color but is expensive.

3. General Selection Guidelines

- Cost-Sensitive: Prioritize air, but consider maintenance trade-offs.

- Quality-Focused: Nitrogen (high purity) or oxygen (carbon steel).

- Efficiency-Focused: Air or oxygen (with negative focus).

Note: Gas purity significantly affects cut quality. High-purity nitrogen reduces impurities, resulting in smoother edges.

undefined

Contact Us

Tel/Wechat:

General Rong : +86 18519765888

E-mail:roger@jattragroup.com

Fax: 022-89898989

Address: No.182 Xiangyuan Road, Jingjin Science and Technology Valley Industrial Park, Wuqing District, Tianjin, China

2015-2025 Jingchuang (Tianjin) Laser Technology Co., Ltd © All Copyright

WeChat Sweep Code Us