23

2025

-

05

How to reduce burrs produced during the cutting process of a laser cutting machine

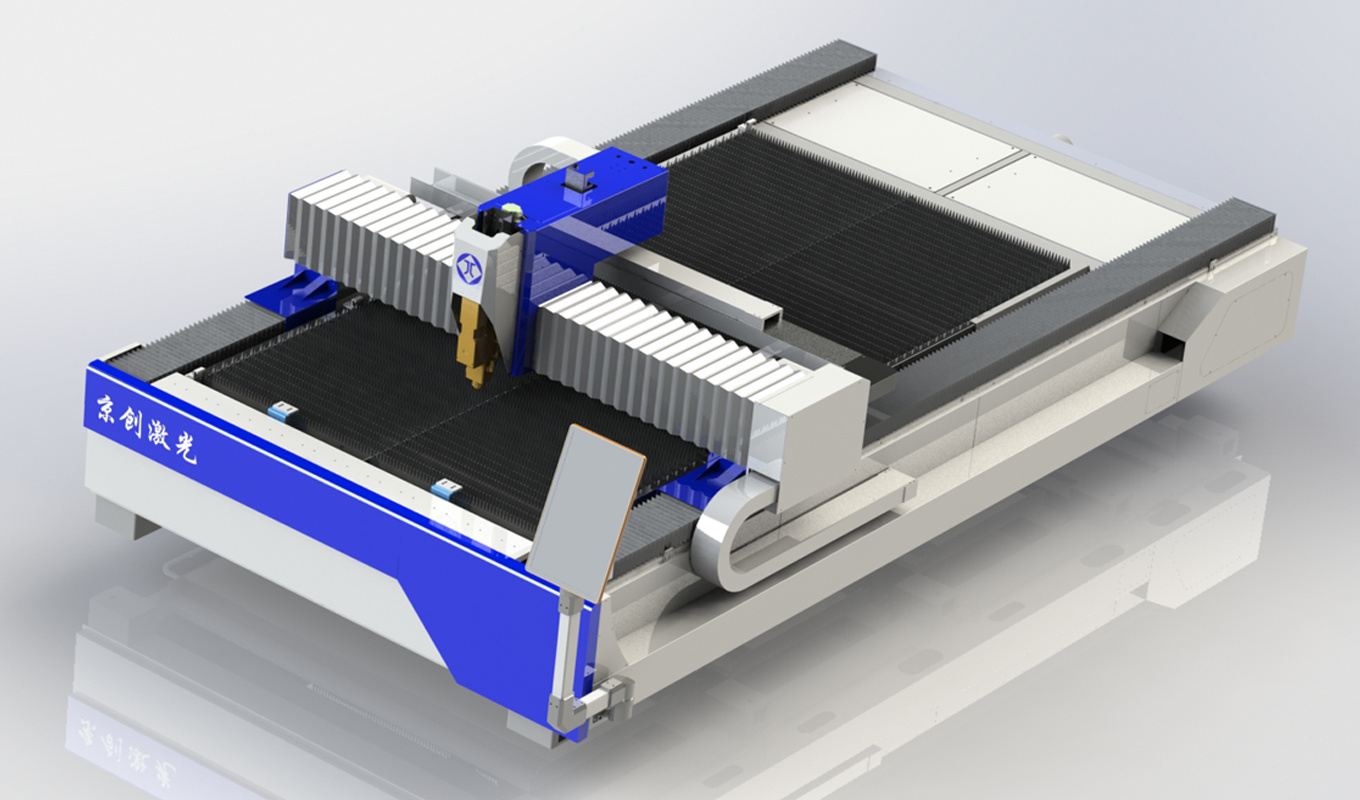

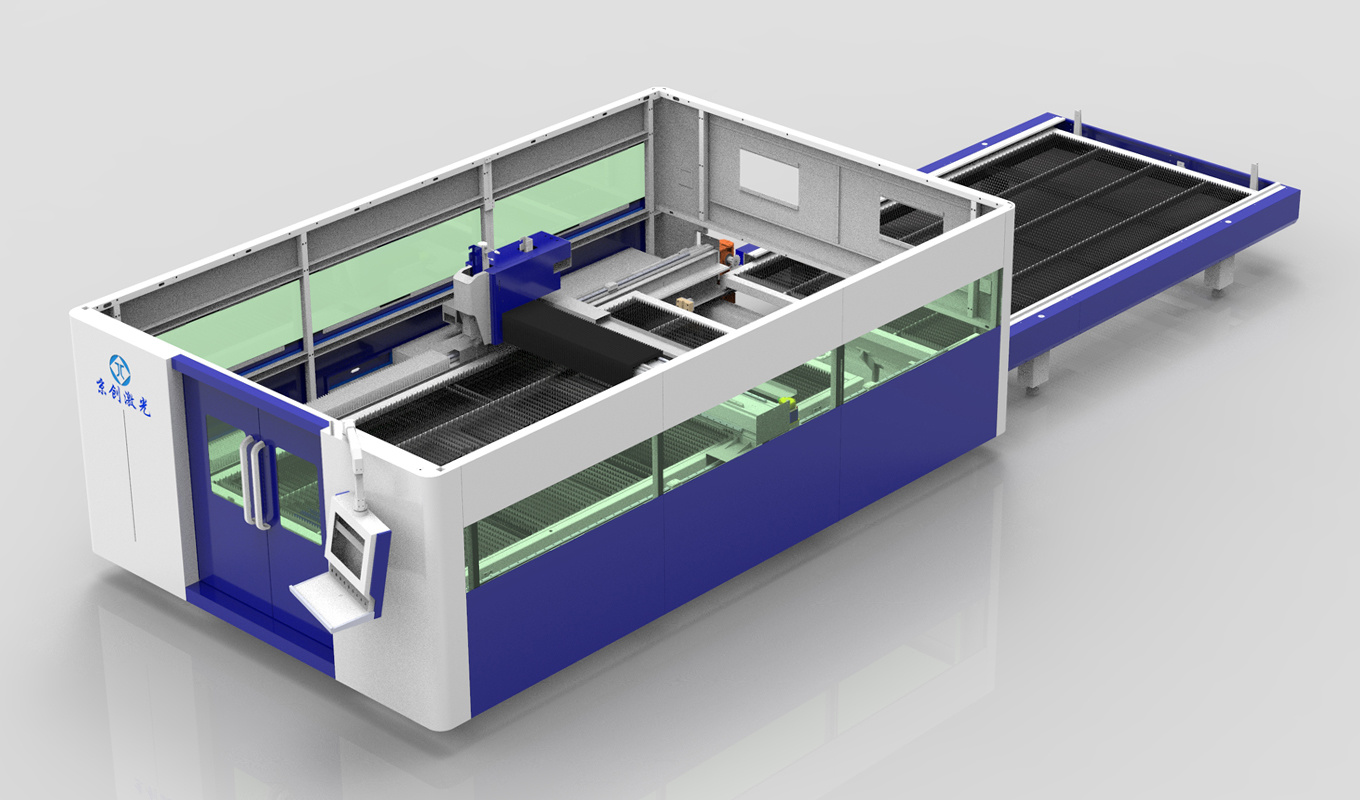

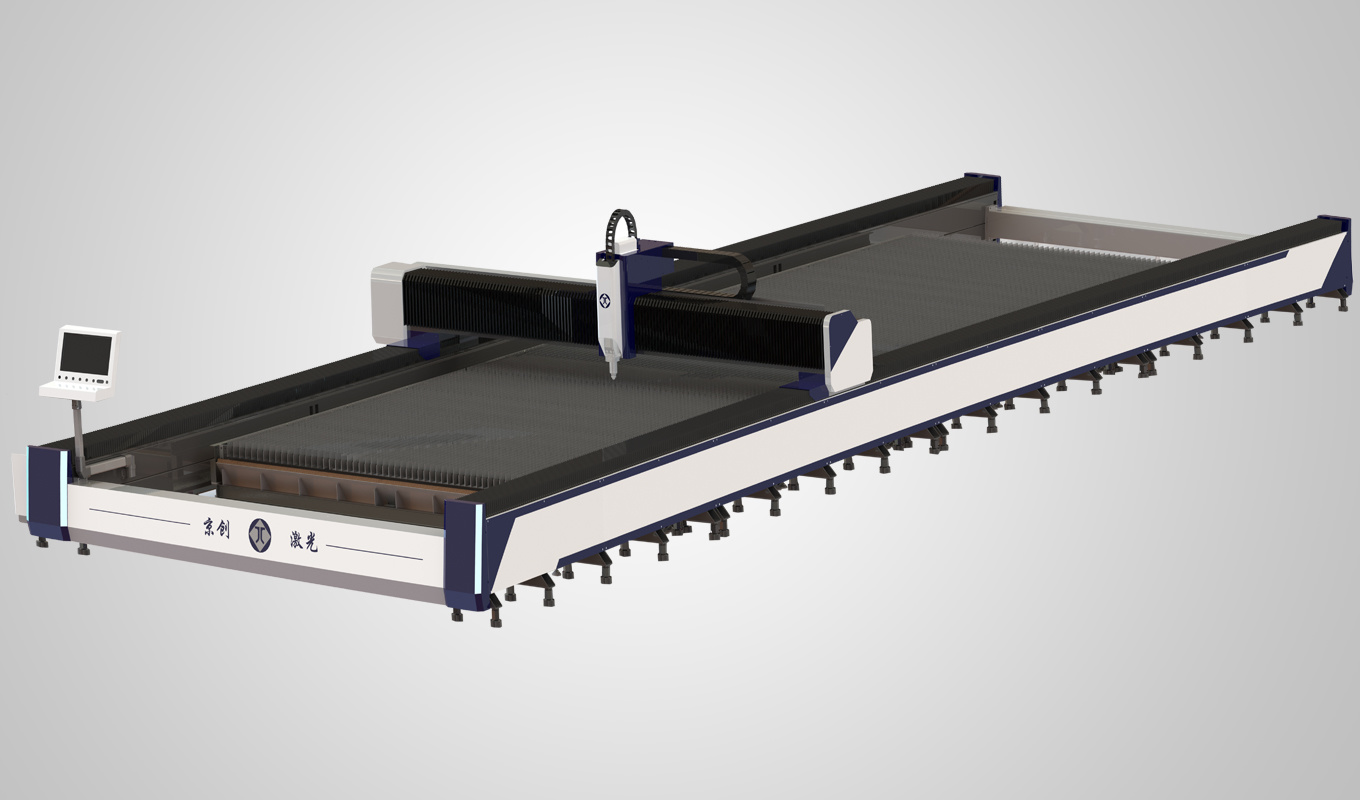

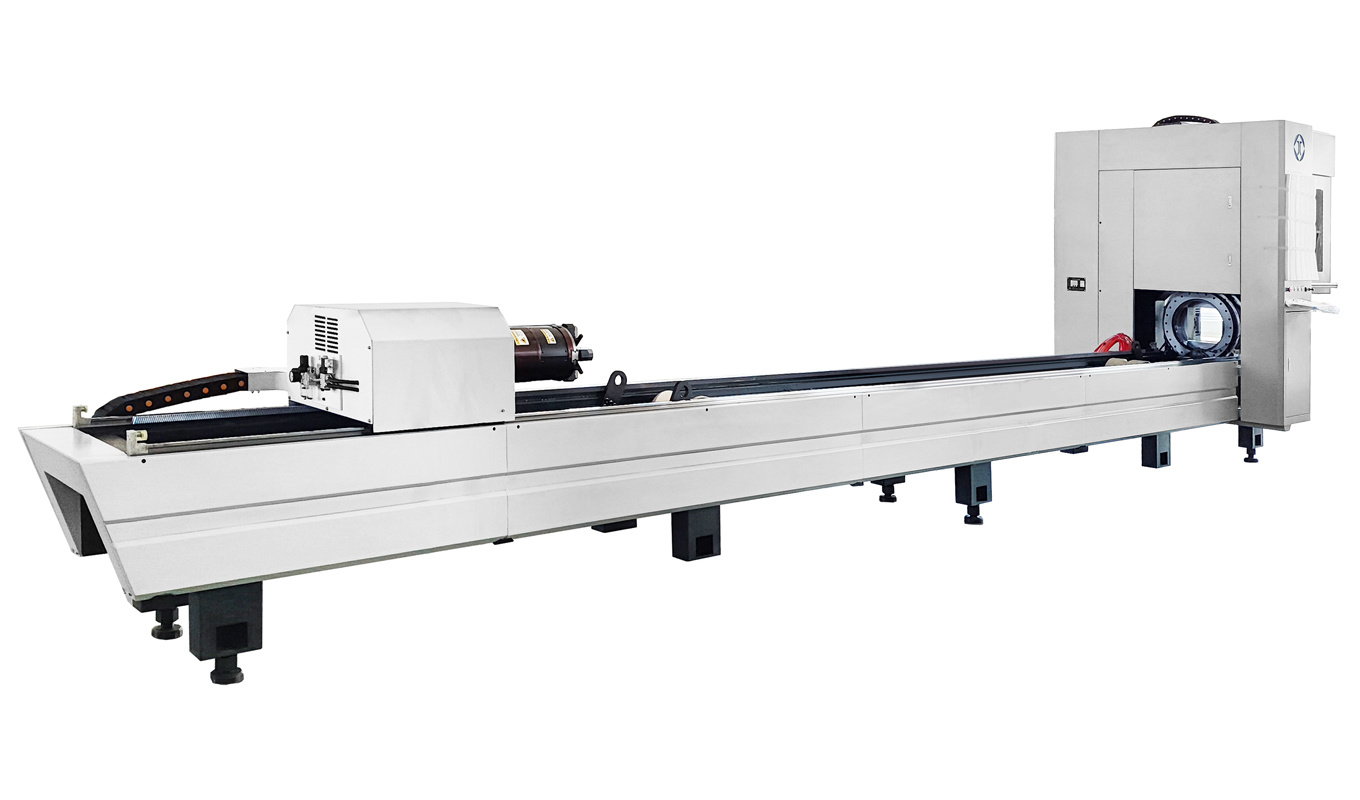

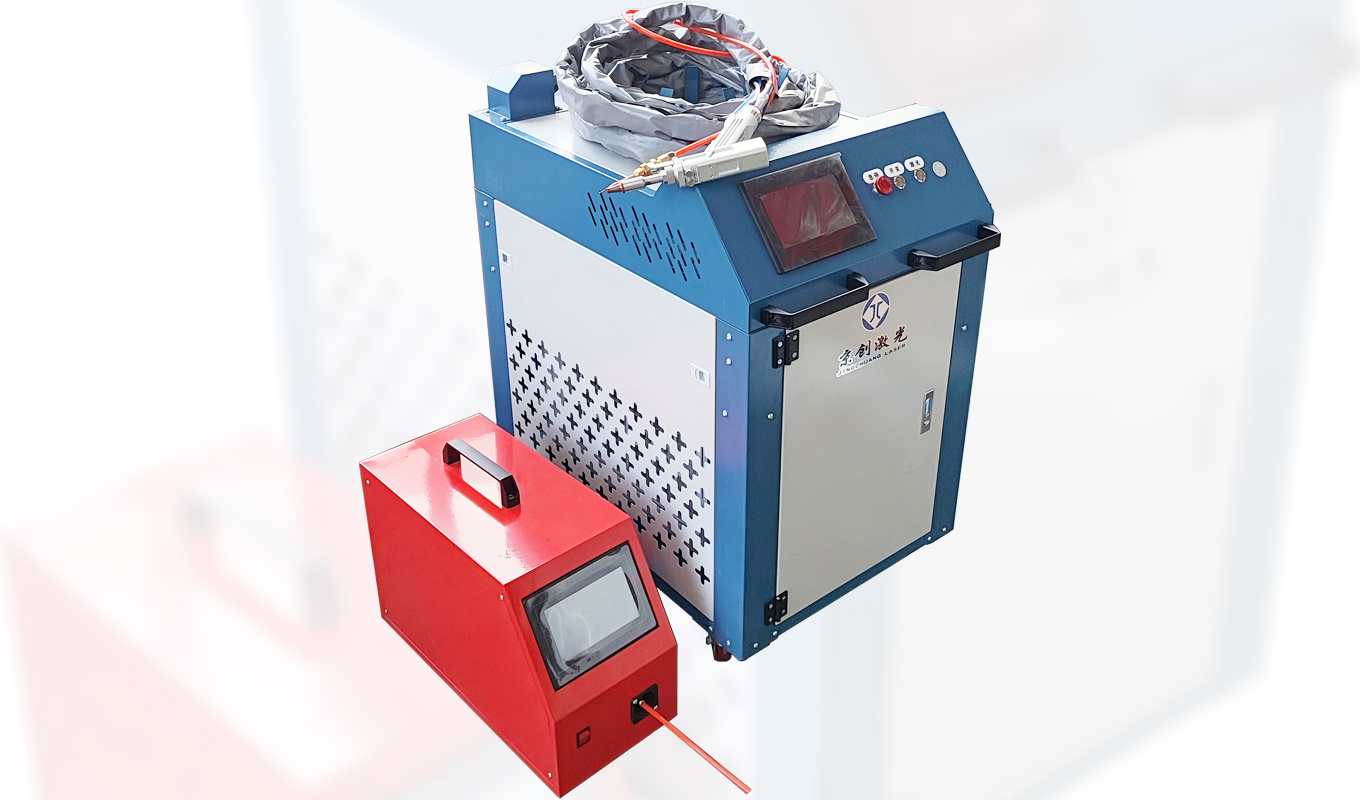

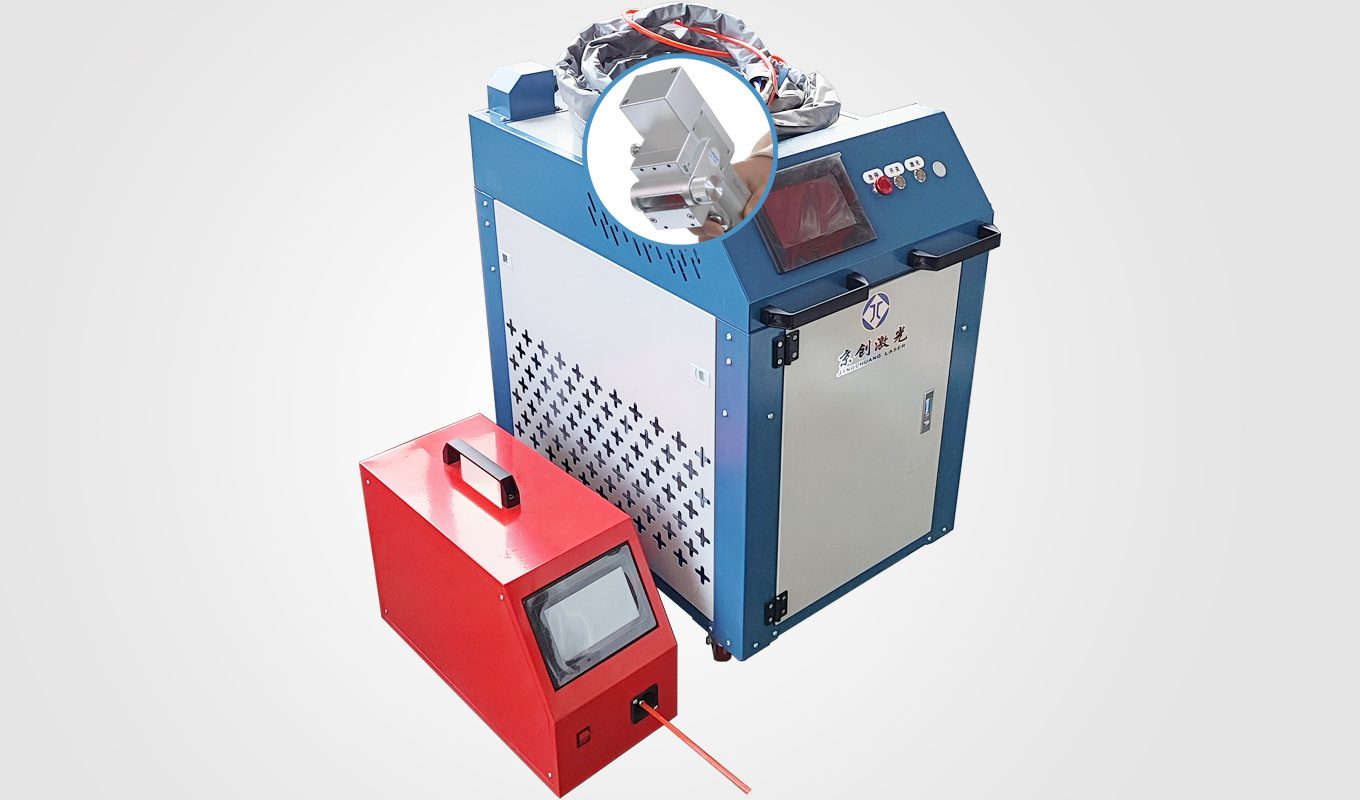

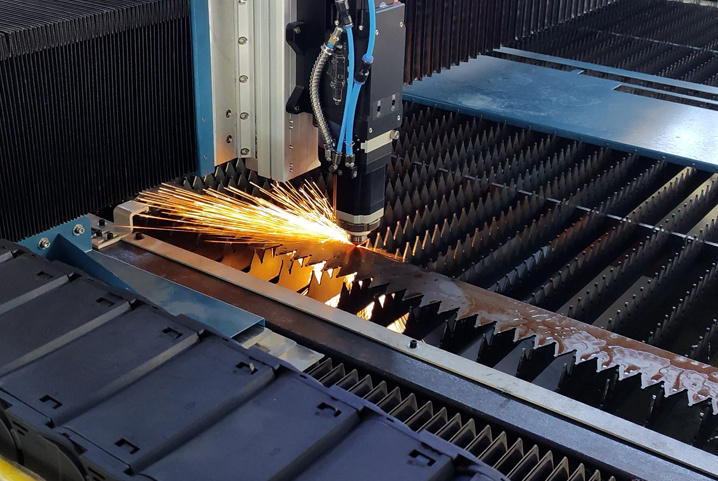

When a fiber laser cutting machine is processing workpieces, the high energy generated by the laser beam irradiating the surface of the workpiece rapidly vaporizes, achieving the purpose of cutting. Burrs are one of the common phenomena in the processing of fiber laser cutting machines. In laser cutting processing, the sharp corners, burrs and other irregular parts that sometimes appear at the transition points on the workpiece surface all belong to burrs. Burrs directly affect the dimensional accuracy, shape and position accuracy, as well as surface roughness of the workpiece.

The main reasons for burrs generated when fiber laser cutting machines process sheet metal:

One is that when the irradiated surface of the workpiece vaporizes, the auxiliary gas blows away the slag on the surface of the workpiece. If no auxiliary gas is used, burrs adhering to the cutting surface will form after the slag cools down.

The second is the equipment itself, parameter setting factors, and daily usage skills. Therefore, after purchasing a new fiber laser cutting machine, customers must undergo professional training before they can start using it.

How to reduce burrs produced during laser cutting:

1.Use auxiliary gas for cutting.

The purity of the gas should be high. It is best not to use gas cylinders because the purity will be poor after two filling processes and the gas will be wasted. When laser cutting stainless steel, it is recommended to use nitrogen as the auxiliary gas. Nitrogen is a flame-retardant gas. During the laser processing, nitrogen not only prevents laser cutting from exploding, but also ensures that the heated end face does not oxidize instantly, making the cut end face smoother and brighter.

2.Have professional operators adjust the parameters of the metal laser cutting machine until they are normal, and then the cutting operation of the fiber laser cutting machine can be successfully completed. Some parameter setting factors of the fiber laser cutting machine can also affect the appearance of the slag, thereby causing burrs on the fiber laser cutting machine. Therefore, the cutting parameters should be adjusted to the optimal state. Adjust the equipment + gas + parameters to the best, ensuring that the cut workpieces have no burrs and making the cutting of the fiber laser cutting machine of higher quality.

Some common causes of burrs and their solutions

1.The up and down position of the beam focus deviates.

Solution: Adjust the position of the focus and make adjustments based on the offset position it generates.

2.The output power of the machine is insufficient.

Solution: Check whether the laser cutting machine is working properly. If any abnormality occurs, timely repair and maintenance are required. If normal, please check whether the output value is correct.

3.The wire cutting speed of the fiber laser cutting machine is too slow.

Solution: Adjust and increase the wire cutting speed in a timely manner.

4.The purity of the auxiliary gas for the fiber laser cutting machine is insufficient.

Solution: Explain how to improve the purity of the auxiliary gas.

5.The addition point of the laser beam of the fiber laser cutting machine has shifted.

Solution: Debug the focus and make timely adjustments.

6.The fiber laser cutting machine operates for too long and is unstable.

Solution: Shut down the machine and restart it to allow it to rest.

fiber laser cutting machine,laser cutting machine,laser cutter,laser cutting machine manufacturer

Previous Page

undefined