240inch Hydraulic Press brake

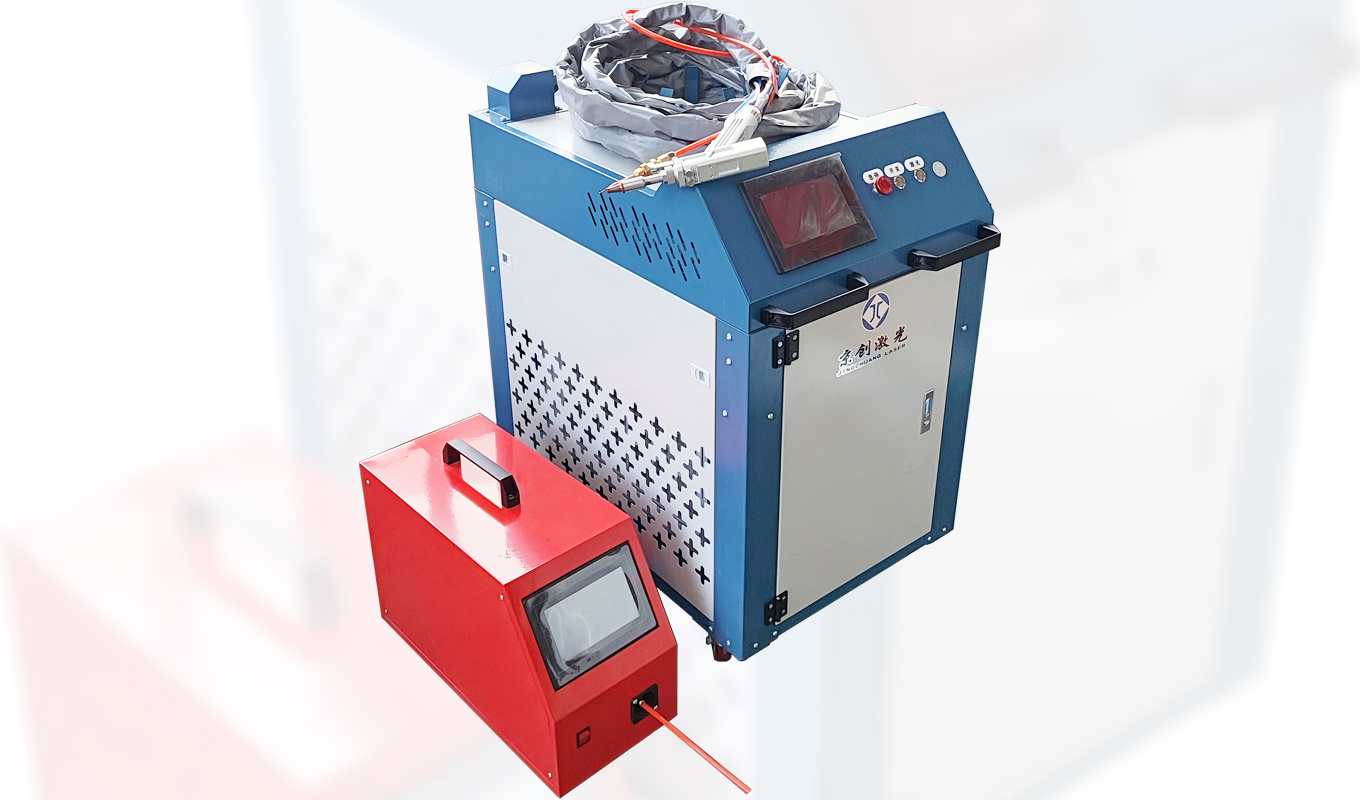

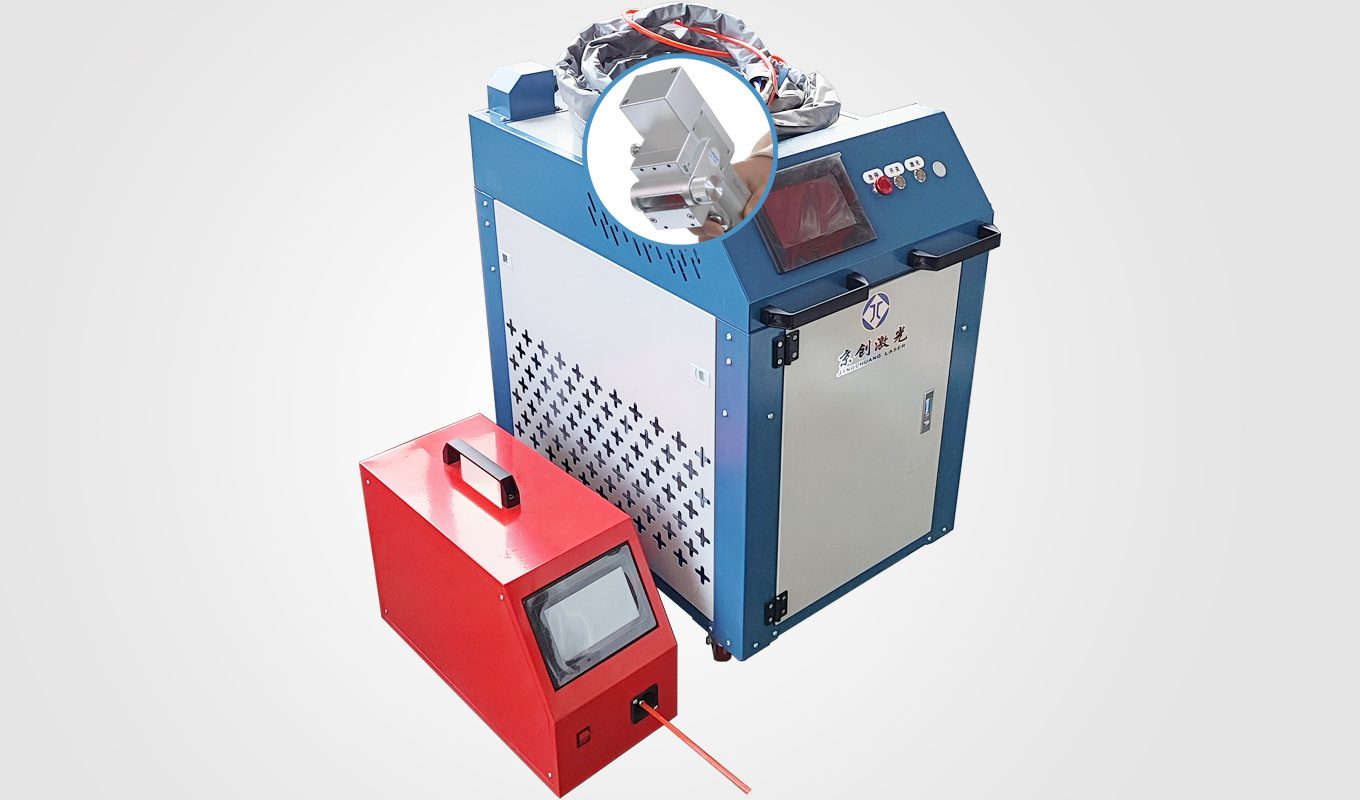

CNC system, can set multi-step program, more efficient. With different molds, it can achieve different angles of bending, flattening and other functions, electronic hydraulic pressure, electro-hydraulic servo correction, higher efficiency and accuracy.

Key words:

240inch Hydraulic Press brake

Classification:

240inch Hydraulic Press brake

Fully automatic calculation, efficient automatic bending, equipped with manipulator, greatly reduce labor costs

Machine parameters:

| Model | CNCH-JC10 | CNCH-JC15 | CNCH-JC25 | CNCH-JC32 | CNCH-JC41 | CNCH-JC51 | CNCH-JC61 | Tandem |

| Pressure value(kN)(ton) | 300kN (30ton) | 400kN (40ton) | 800kN (80ton) |

1100kN (110ton) 1700kN (170ton) 2500kN (250ton) |

1100kN (110ton) 1700kN (170ton) 2500kN (250ton) 3200kN (320ton) |

1600kN (160ton) 3200kN (320ton) |

2500kN (250ton) 3200kN (320ton) |

Customized |

| Processing Length |

1000mm |

1500mm | 2500mm | 3200mm | 4100mm | 5100mm | 6100mm | max 12000 meters |

| Pressure speed (mm/s) |

8~15 mm/s |

|||||||

| CNC control system |

1.CNC Control system, multi-step programming. 2.18 common international languages. |

|||||||

| Precision |

Electro-hydraulic servo calibrate |

|||||||

|

Feature |

Disturbance compensation | |||||||

| Positional |

Y1-Y2-X-R-V 4+1 axis accurate positioning. |

|||||||

| OEM/ ODM |

Color /Sticker /Logo and Customized specification |

|||||||

|

|

|

1000mm length Single Hydraulic pump small CNC press brake machine |

1500mm length Double Hydraulic pump small CNC press brake machine |

|

|

| 3.2 meters (126 inch) CNC plate/sheet metal Hydraulic press brake |

4.1 meters (161 inch) CNC plate/sheet metal Hydraulic press brake |

|

|

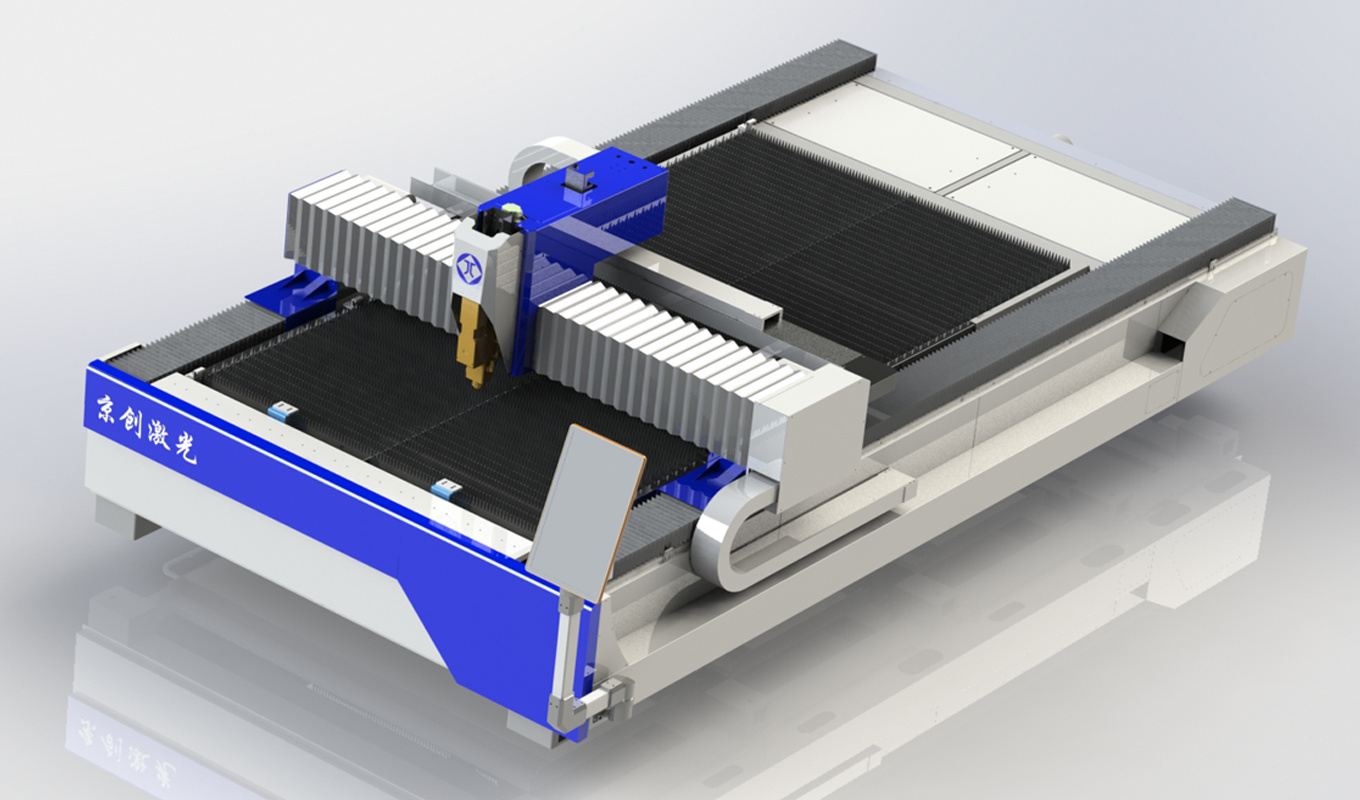

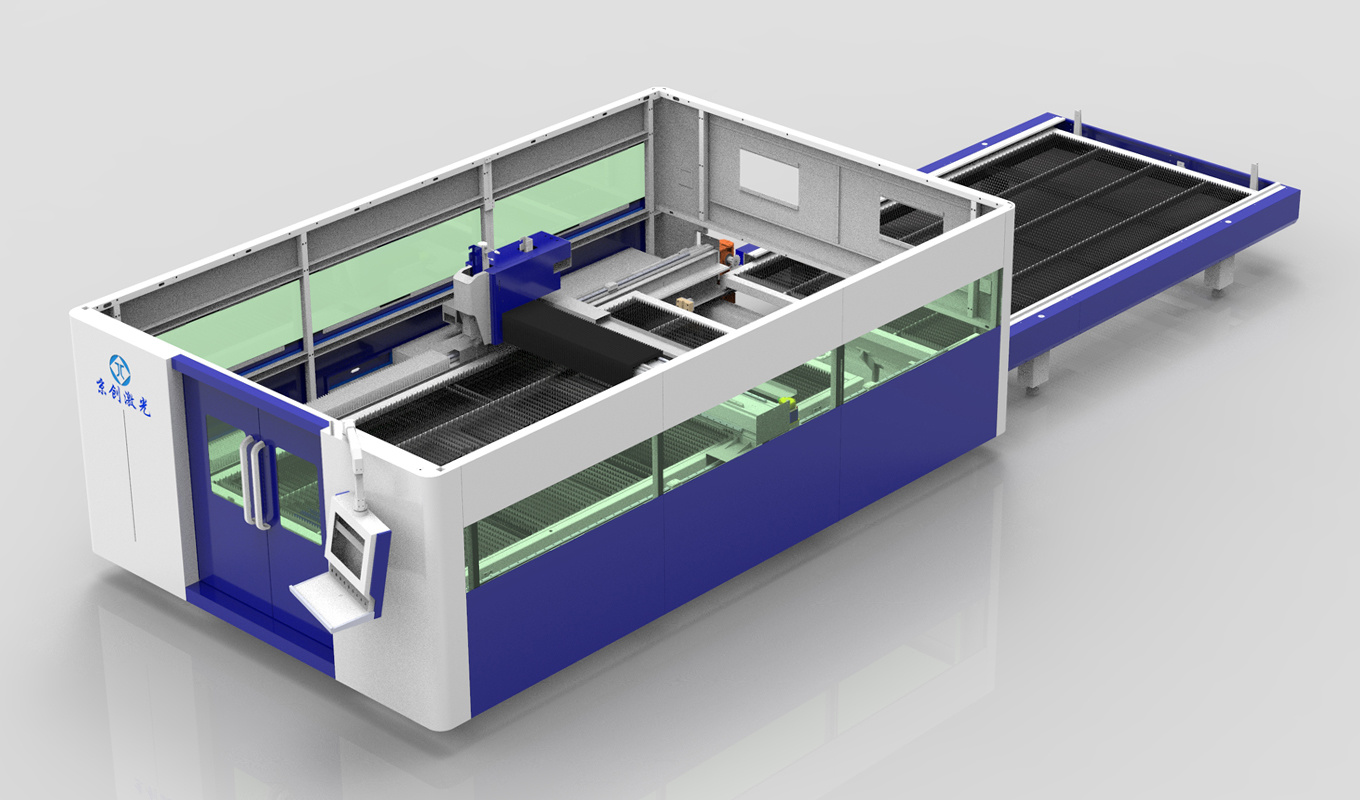

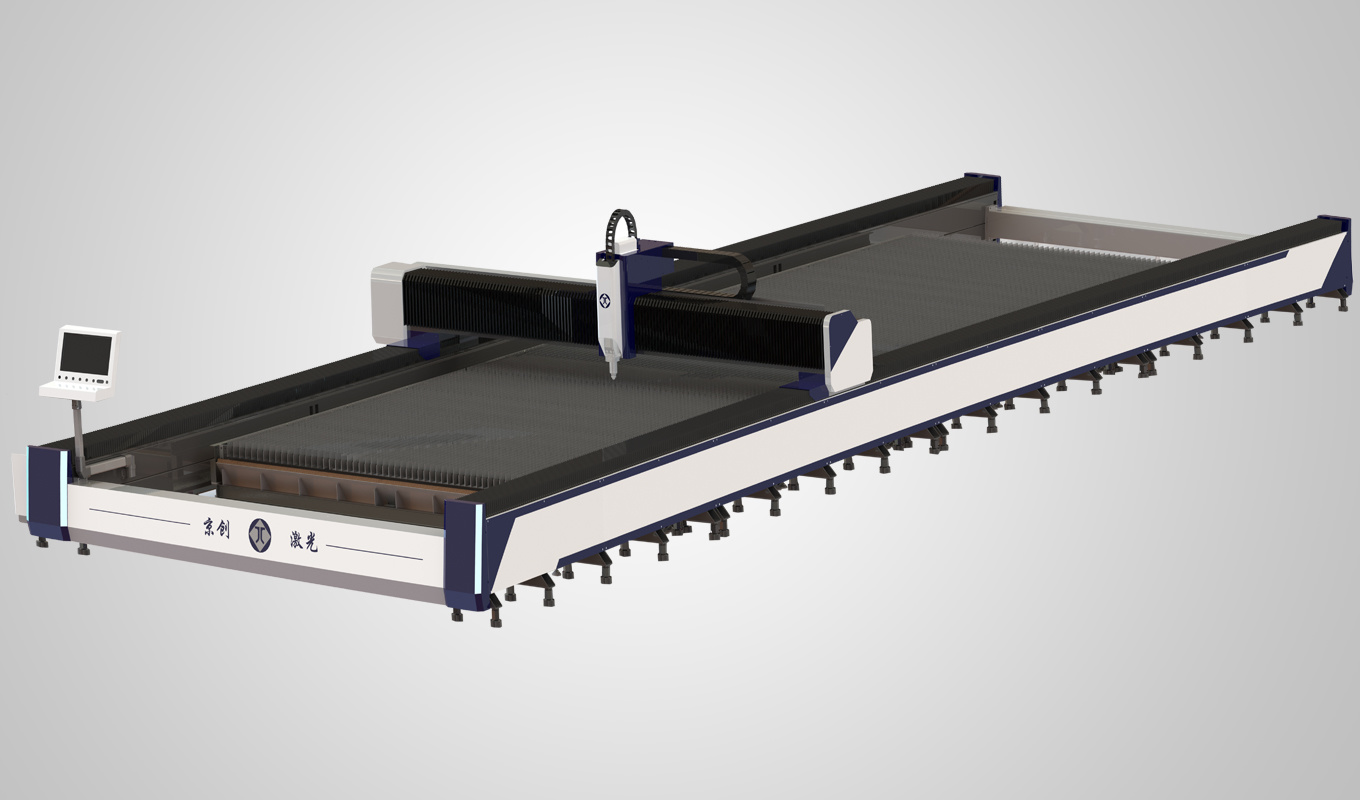

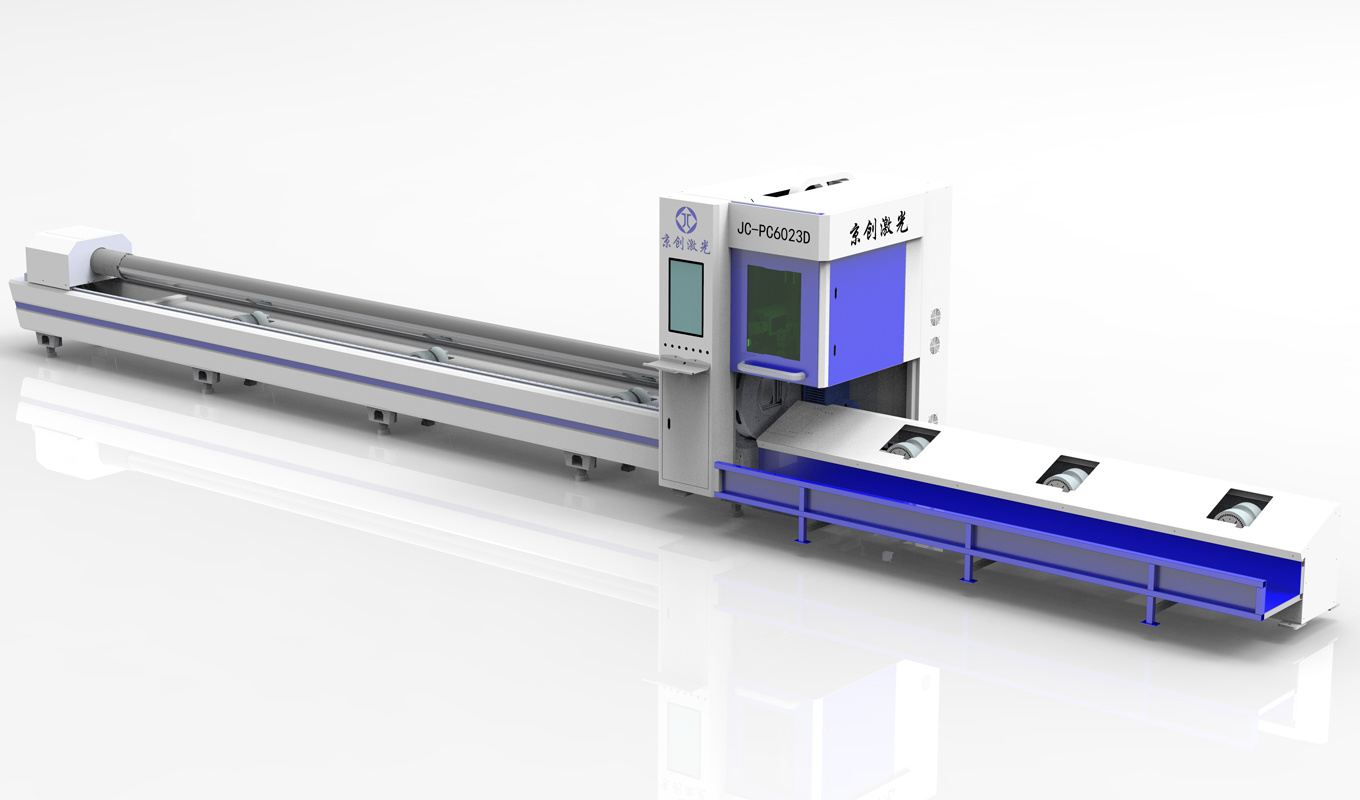

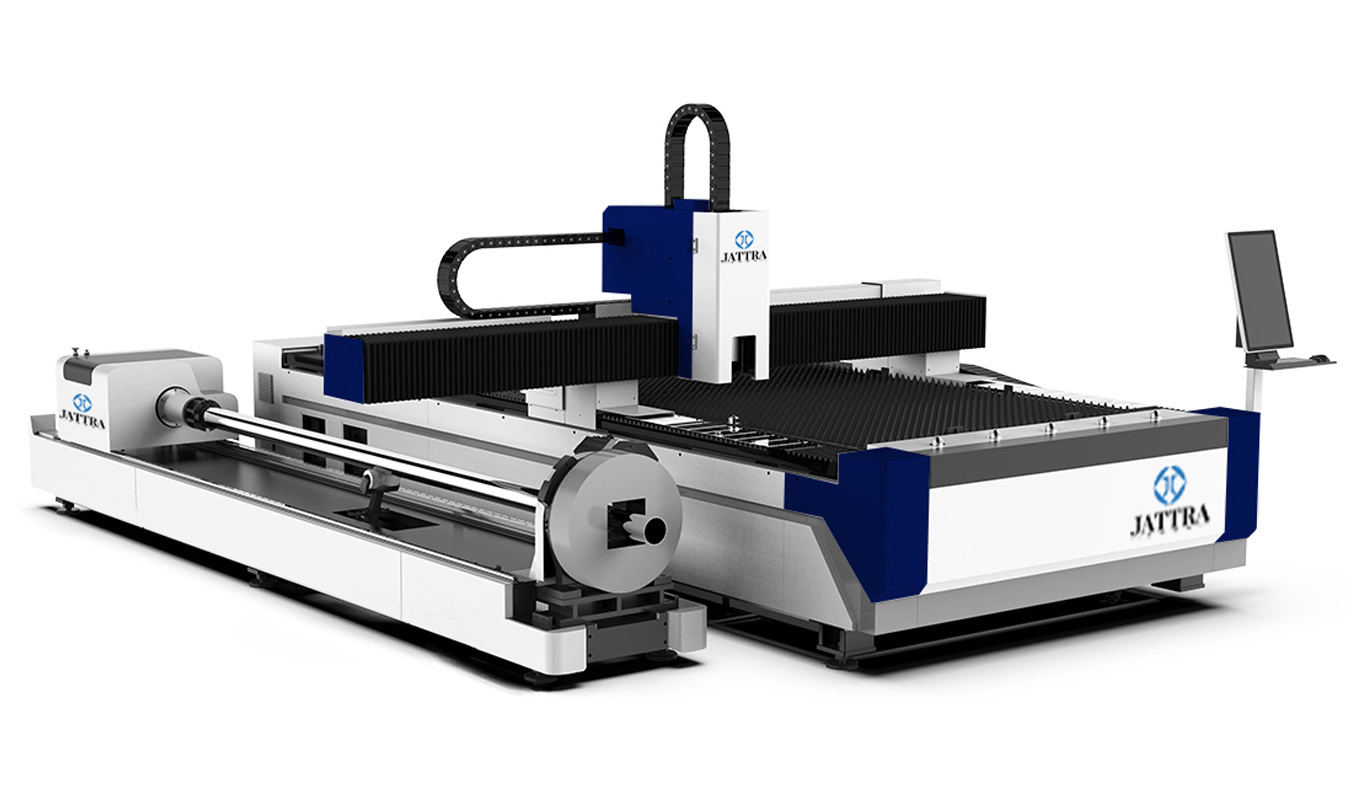

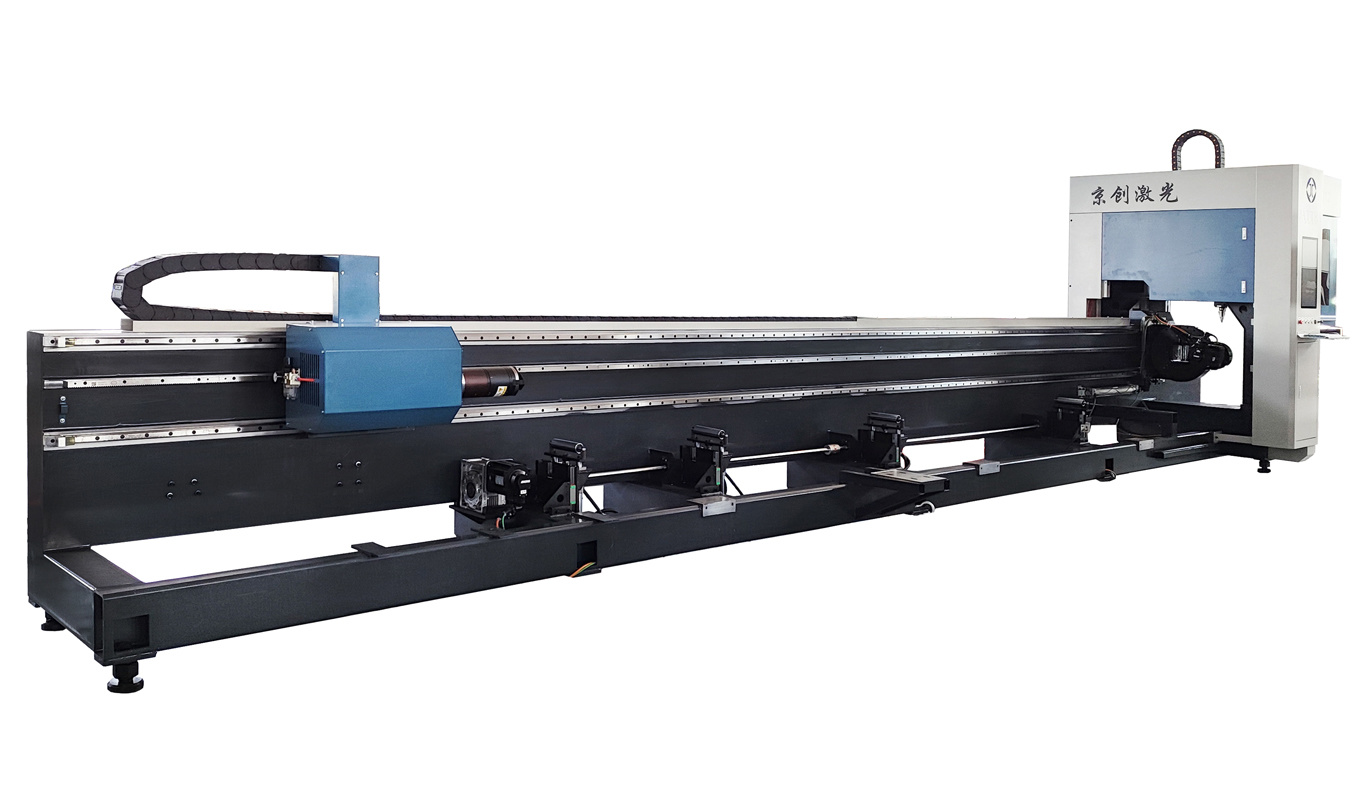

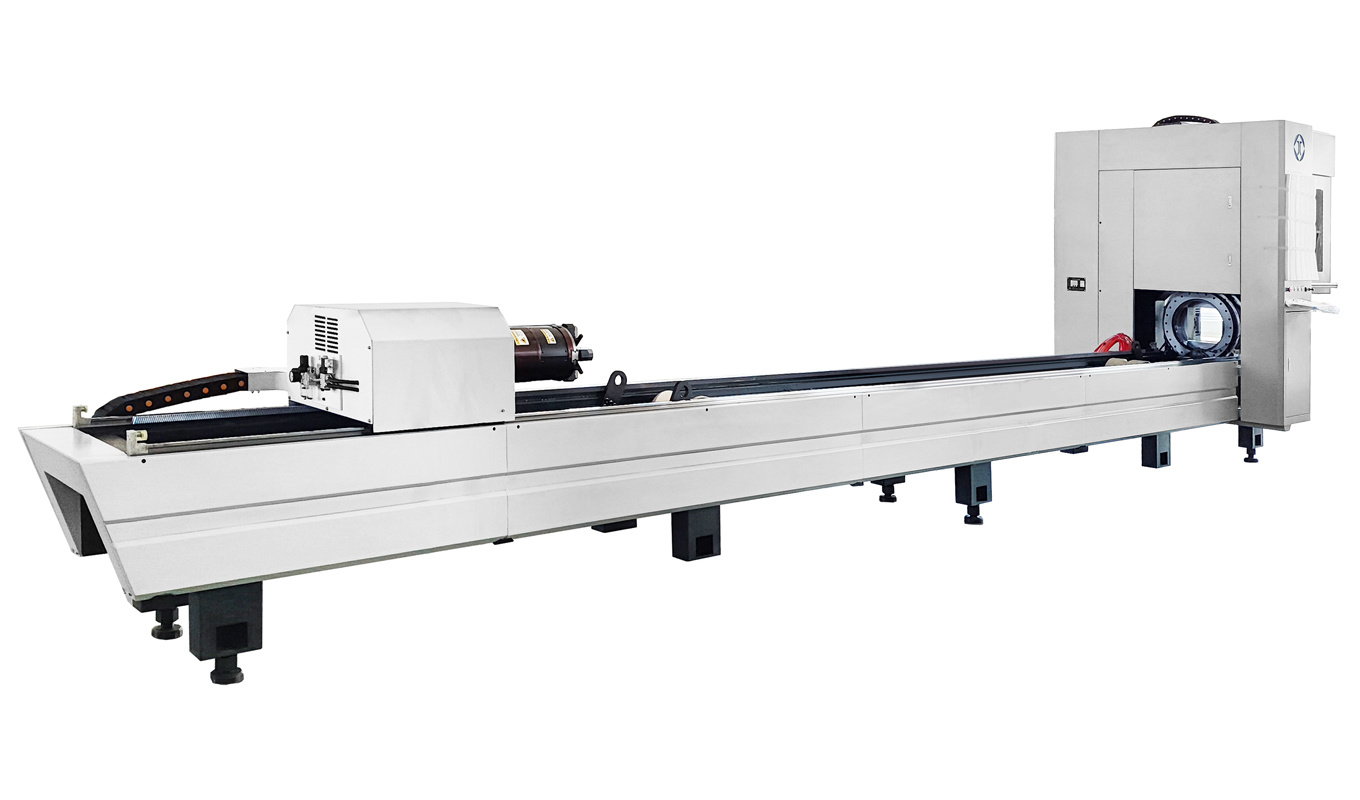

| 6.1 meters length (240inch), 2500kN, about 250tons CNC hydraulic sheet metal bending machine |

Features:

1. The German BoschRexroth professional hydraulic system, split valve installed on the top of the cylinder, high response frequency, stable and reliable performance

2. Equipped with Italy GIVI grating ruler, resolution up to 0.005mm

3. Mechanical deflection compensation eliminates the influence of slider deformation on the quality of the workpiece. The CNC system automatically adjusts the compensation amount, which is convenient and accurate to operate

4. Slider position feedback precision is high, the operation is accurate and stable, the synchronization performance is good, the bending accuracy, the slider repeat positioning accuracy is high.

Application areas:

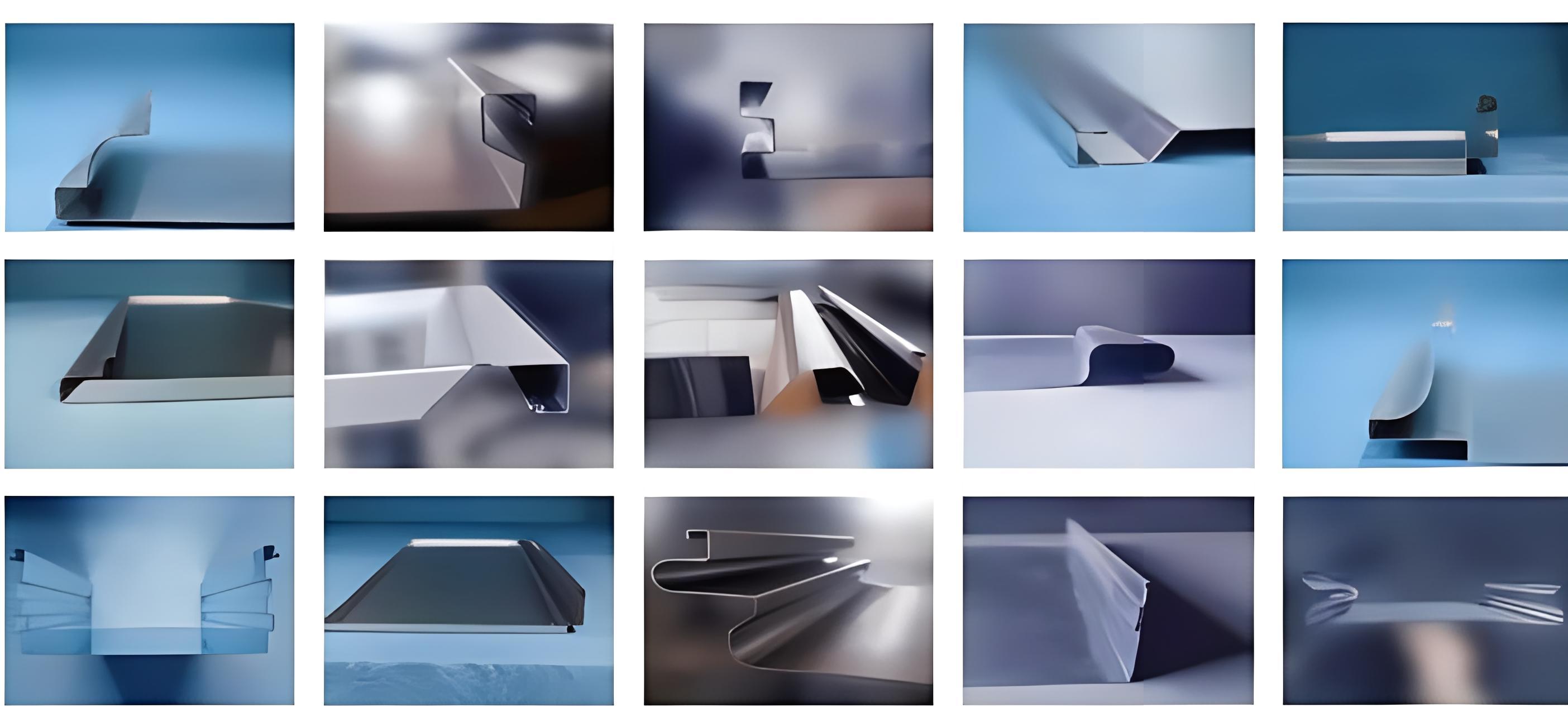

Suitable for carbon steel, stainless steel, galvanized sheet, galvanized sheet, alloy steel.

It is widely used in aviation, metallurgy, shipbuilding and other national key industrial fields, as well as automobile, machinery, sheet metal, packaging, kitchen utensils, sports equipment, elevator electrical appliances, advertising signs and other manufacturing industries.

Processing samples display:

Previous Page

Next Page

Previous Page

Next Page

Related Products

Consulting