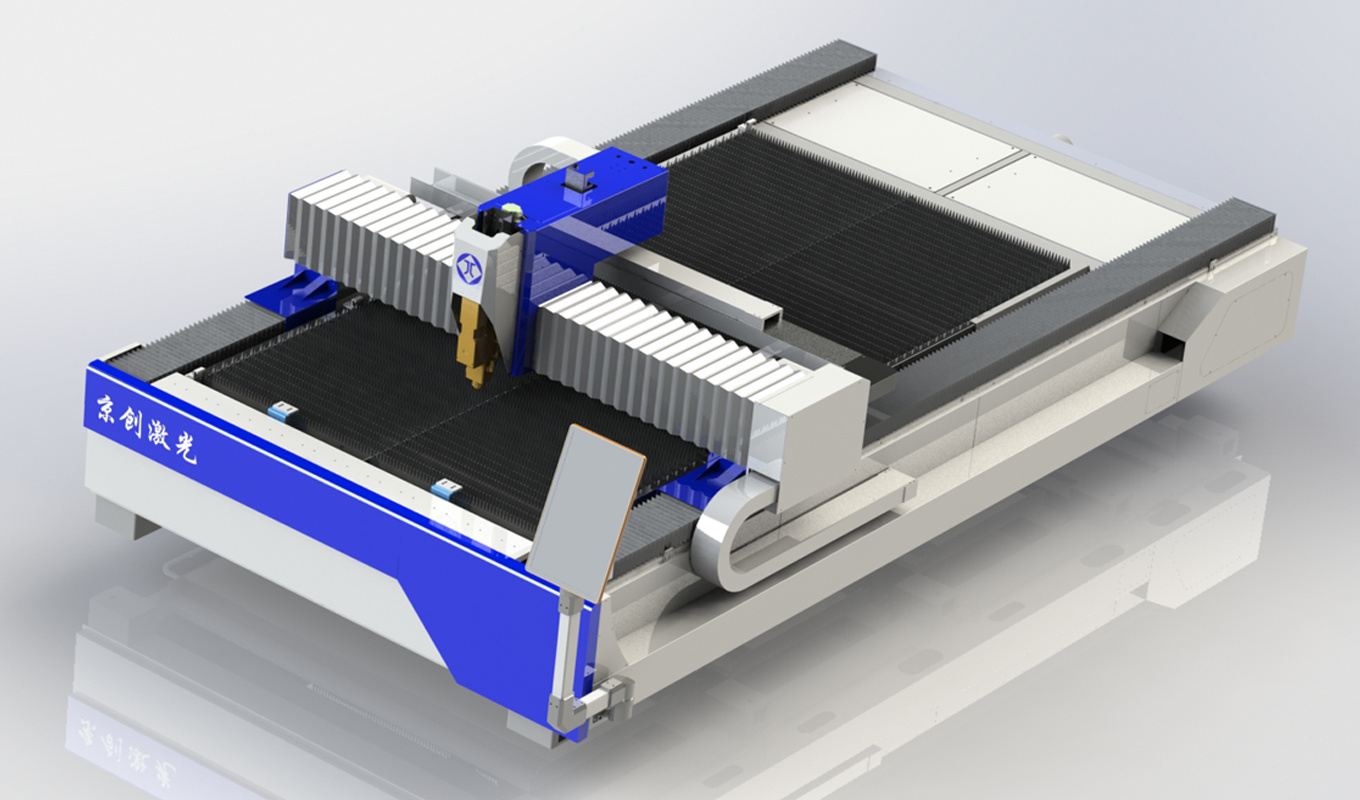

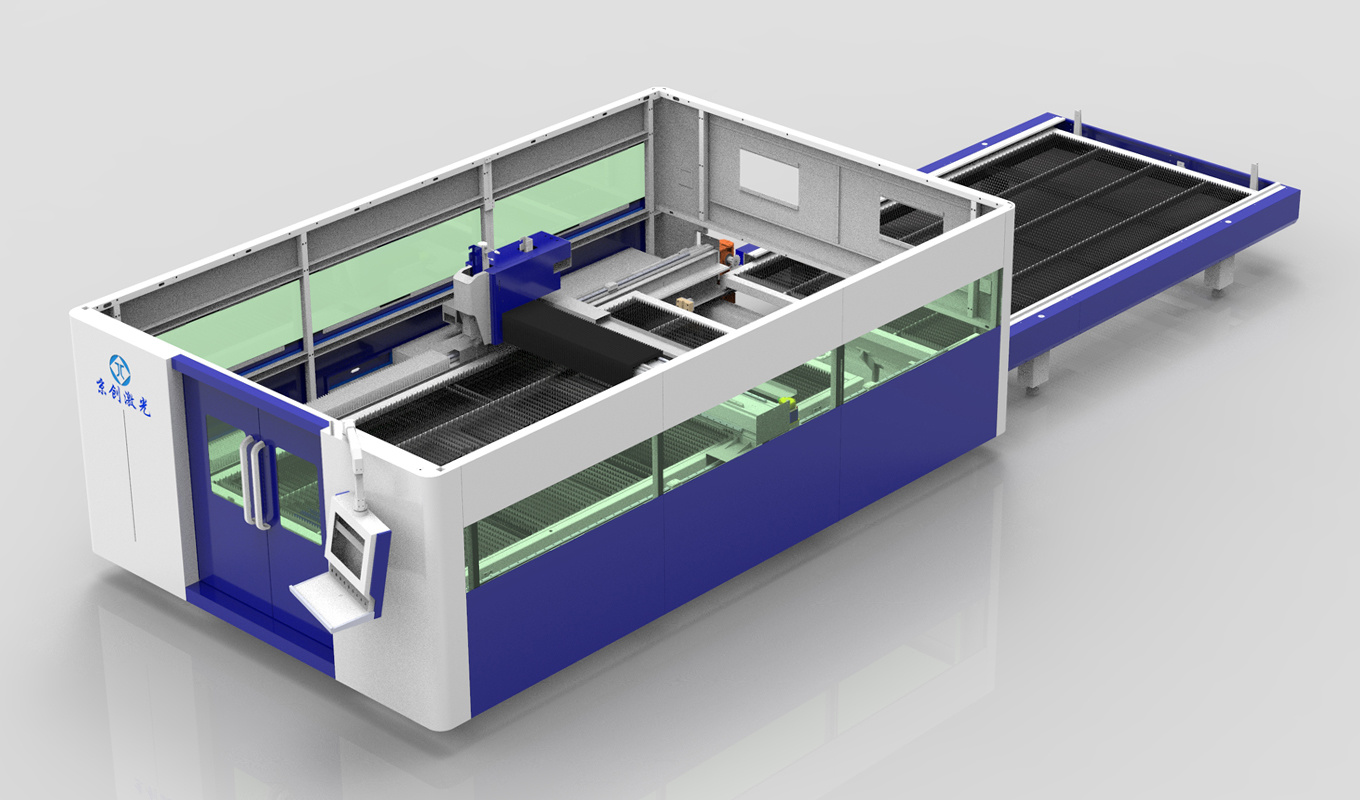

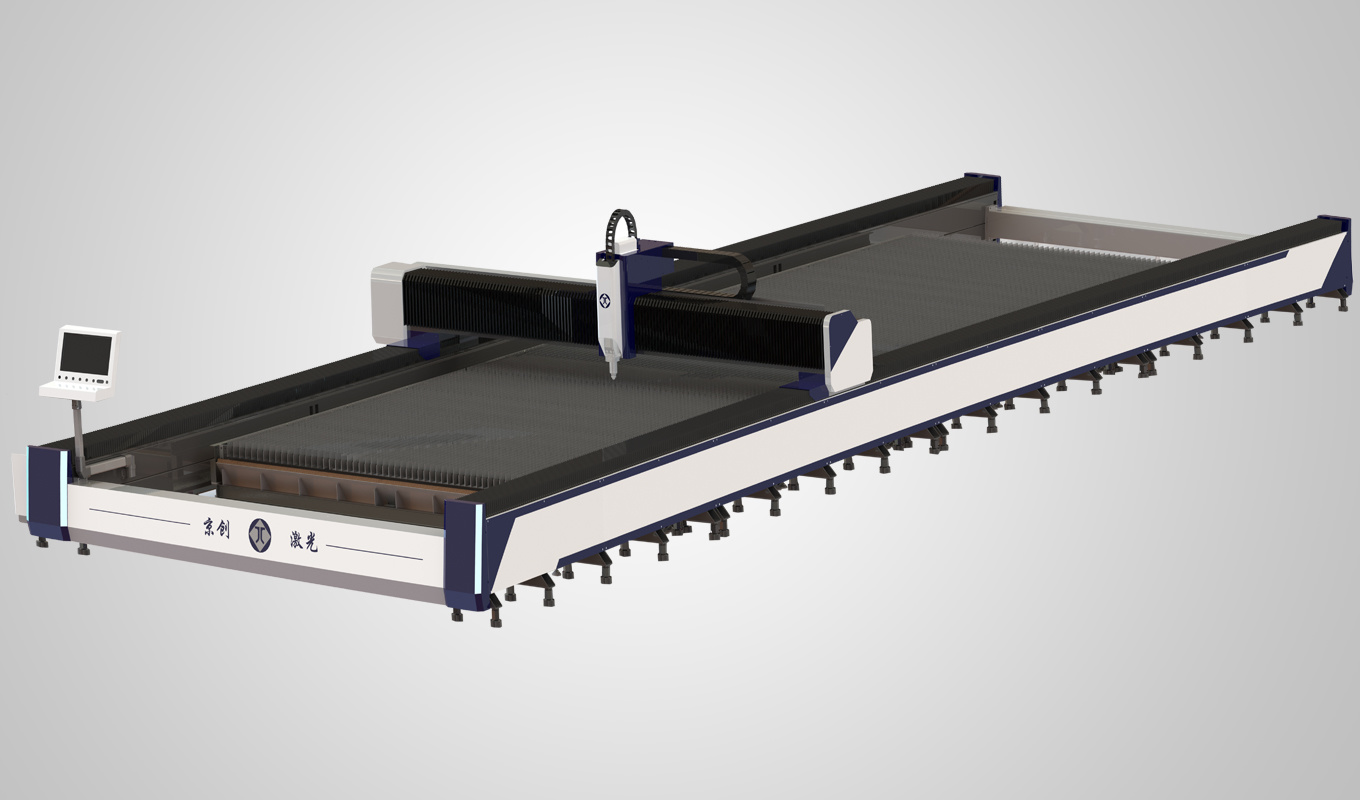

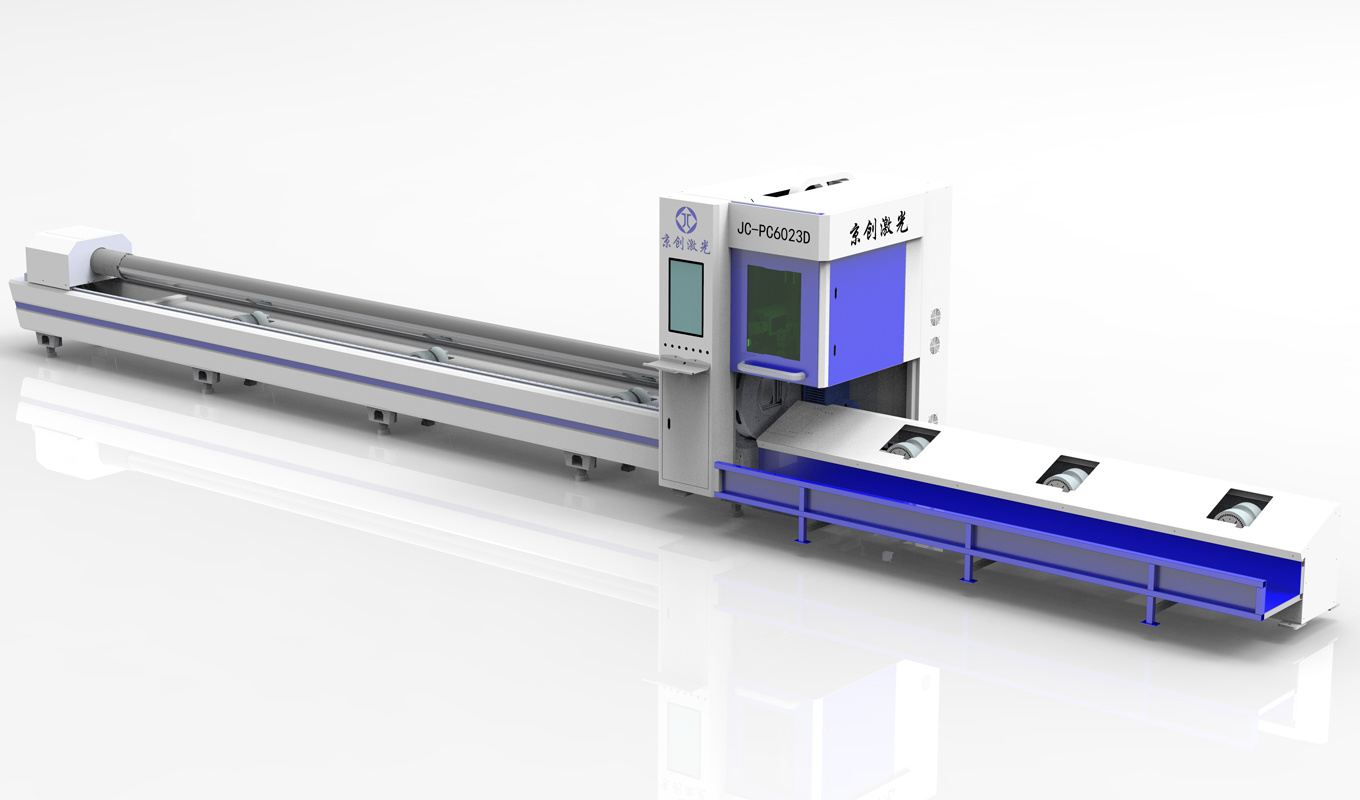

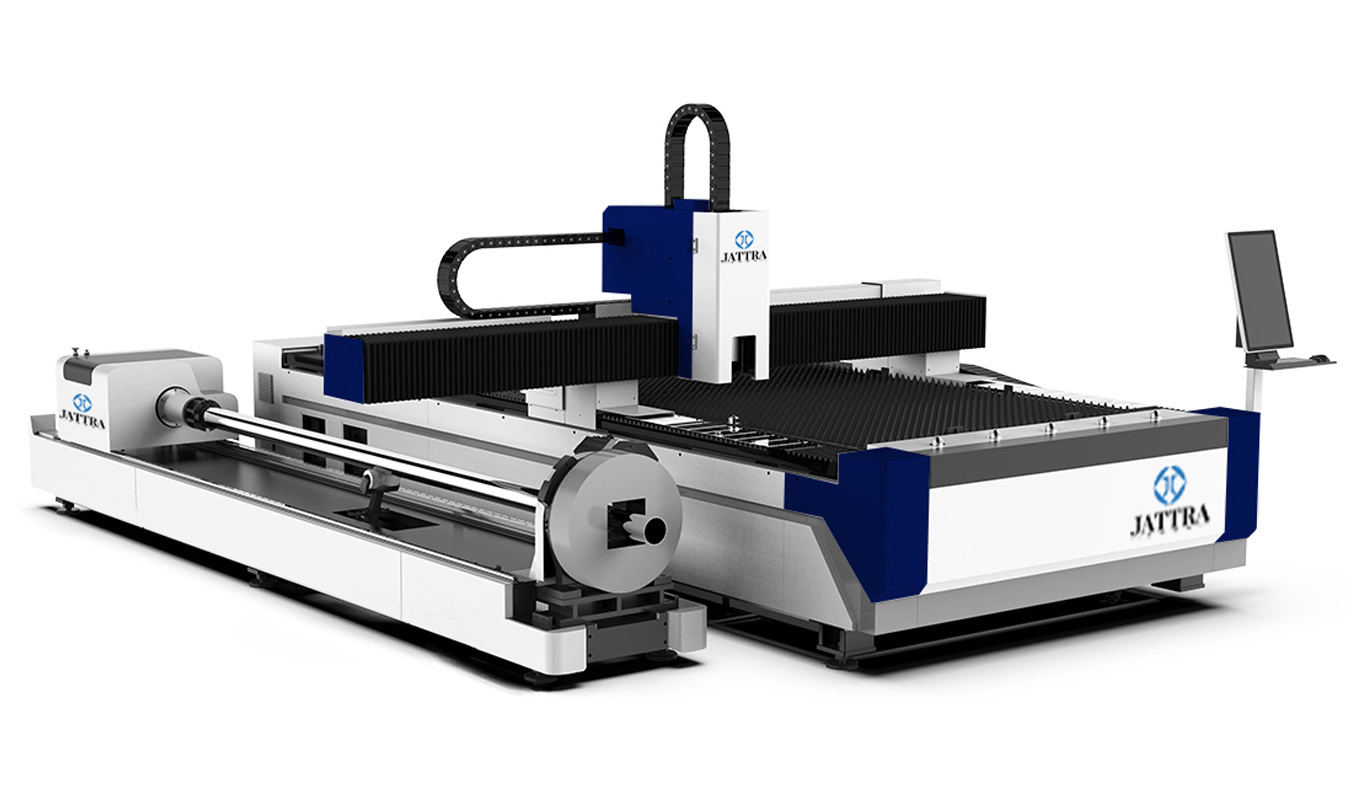

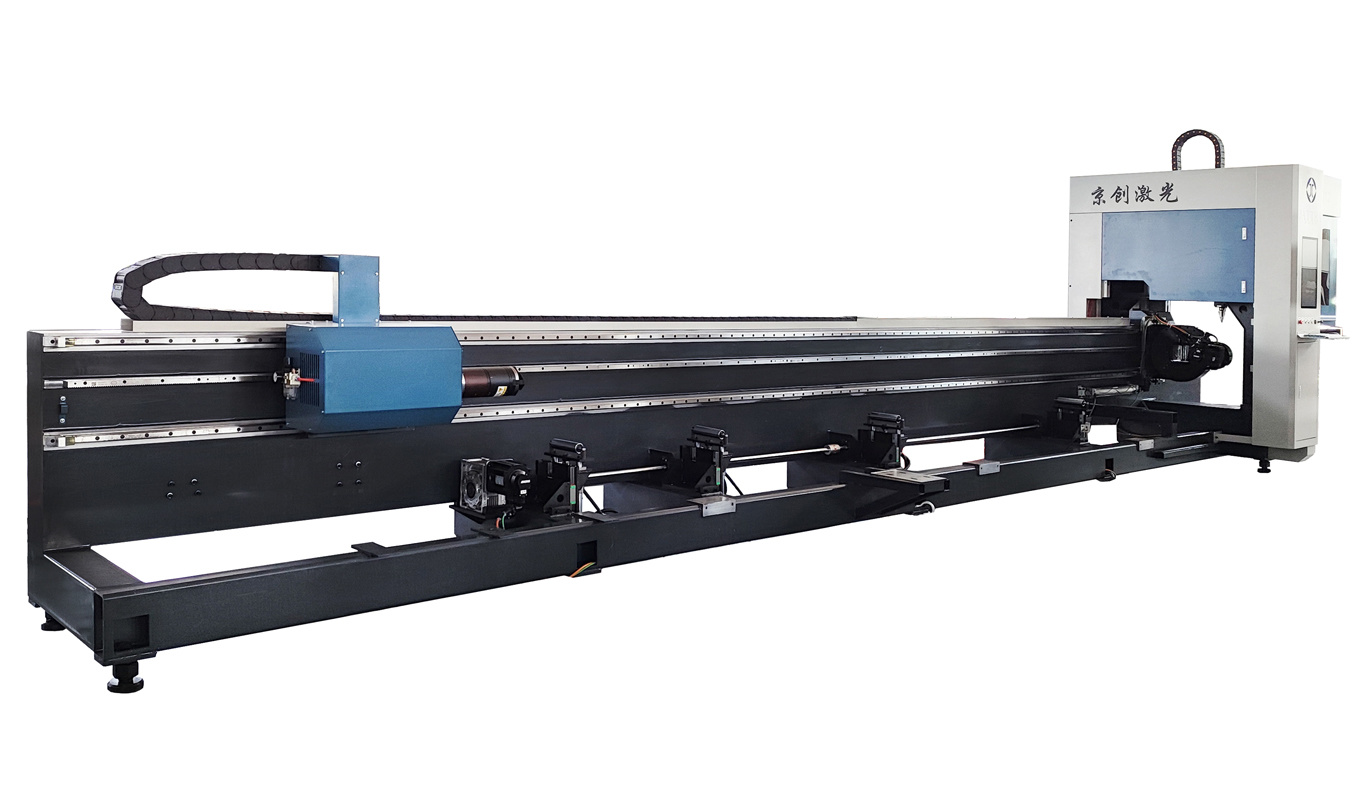

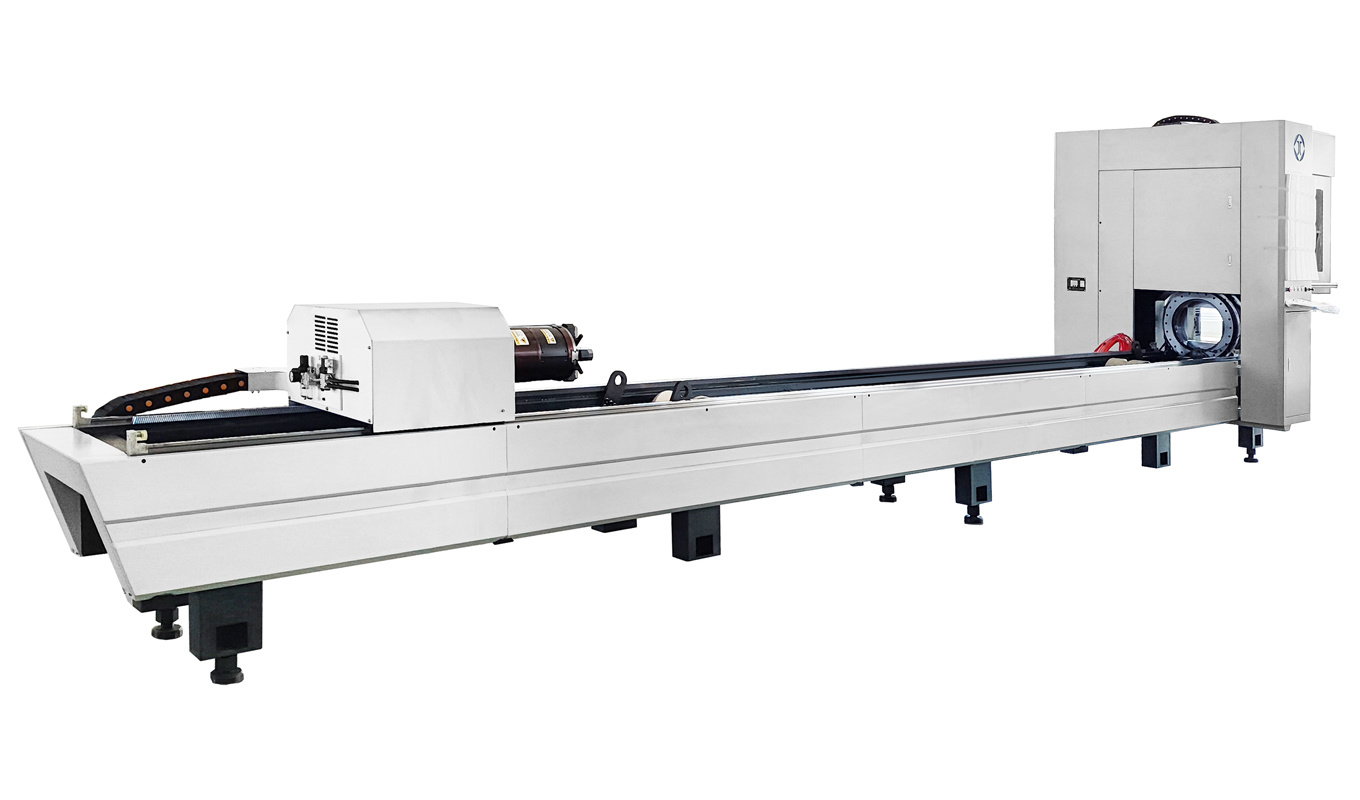

Side hanging Tube Laser cutting machine

Side hanging type, 6 meters long, 350mm lathe chuck, CNC system, 3000W laser power.

Key words:

Side hanging Tube Laser cutting machine

Classification:

Side hanging Tube Laser cutting machine

Machine Parameters:

| Type | Horizontal Type | Side Hanging Type | Customized | ||

| Model |

Two lathe Chucks |

Three lathe Chucks | Two lathe Chucks | Three lathe Chucks | Customized |

| Working Diameter | 90mm/ 120mm/ 230mm/ 350mm | 170mm/ 230mm/ 350mm/ 550mm | 90mm/ 120mm/ 230mm/ 350mm | 170mm/ 230mm/ 350mm/ 550mm |

Customized |

| Max Working Length (meters) | 6 meters and longer | 6 meters and longer | 6 meters and longer | 6 meters and longer | 6 meters and longer |

| Max Working Length(mm) | 6000mm and longer | 6000mm and longer | 6000mm and longer | 6000mm and longer | 6000mm and longer |

| Laser Power | 1500W/ 3000W/ 6000W | 3000W/ 6000W /8000W /12kW /20kW | 1500W/ 3000W/ 6000W | 3000W/ 6000W /8000W /12kW /20kW |

Optional: 1500W/ 3000W /6000W /8000W /12kW /20kW and more |

| Function |

Vertical cutting/ Angle cutting/ Laser slotting/ Laser engraving |

||||

| Support Device | 1. servo chuck device, 2.servo Prop up device, 3.automatic uploading tube device, 4.automatic unloading tube device. | ||||

| Cutting Material |

Carbon Steel/ Iron/ Stainless steel/ Aluminium alloy/ Copper/ Brass/ Mg-alloy/ CrMo steel |

||||

| Cutting Precision |

<0.02mm |

||||

| Control System |

1.CNC Control System with 18 Languages 2.Support Enter the values/ Import the drawing |

||||

| Supported file format: |

.DXF /.EMW /.NC /.NSP and more |

||||

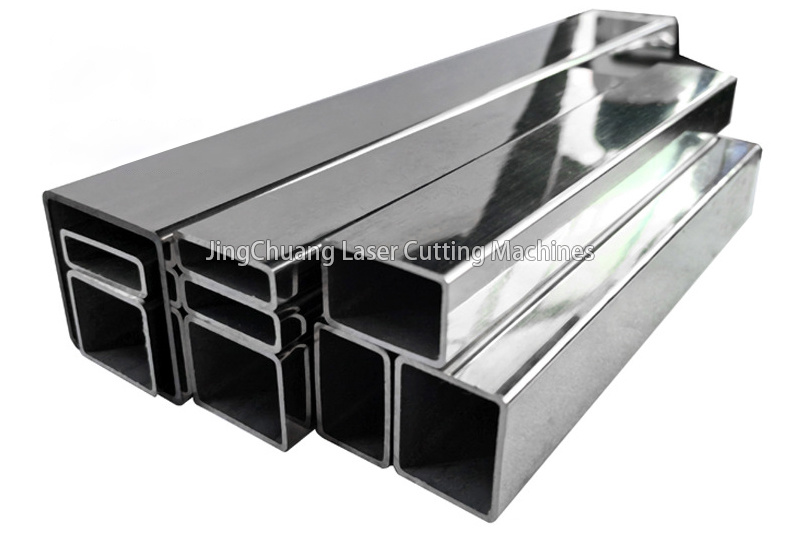

Cutting Material

| Round Tube | Rectangular Tube/ Square Tube | Special shape Pipe |

|

|

|

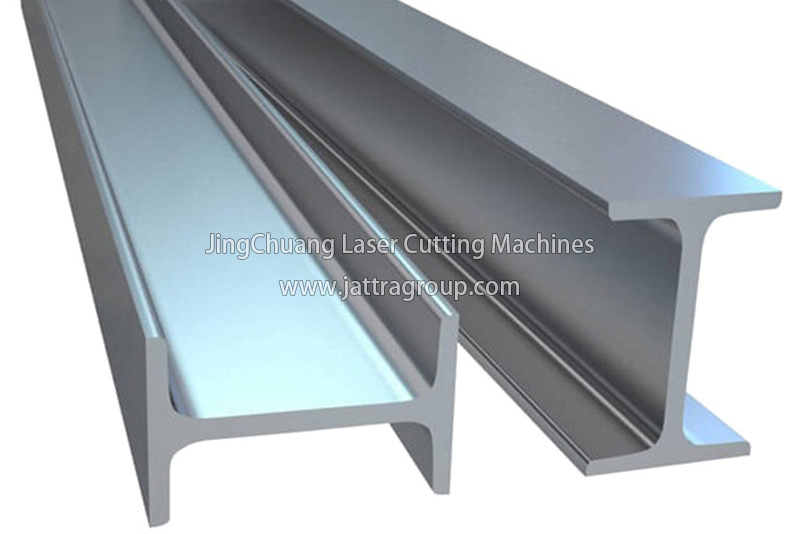

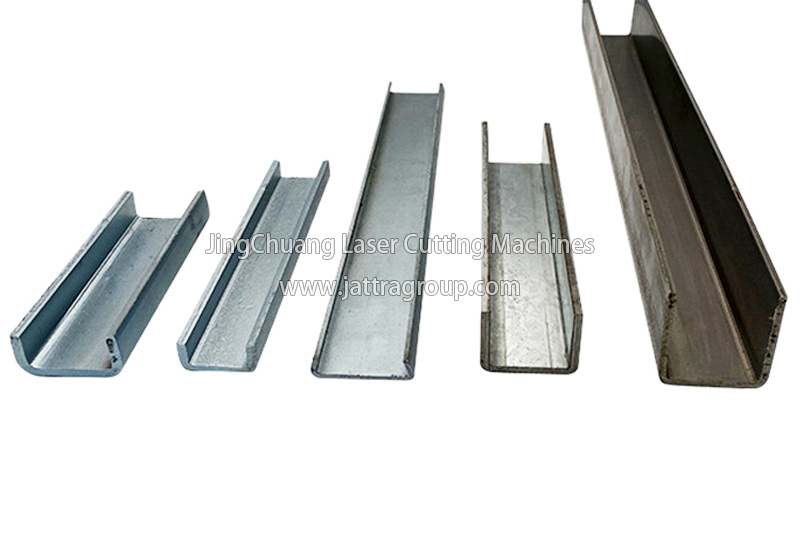

| I-Beam / H-Beam Strip Steel | Angle steel/ L shape Strip steel | U shape/ C shape Strip Steel |

|

|

|

Optional automatic loading and unloading configuration, easy to achieve large quantities of the same specifications of the pipe batch processing production

Features:

1. Servo support, precise positioning

2. Large aperture, super clamping force, more inclusive

3. Can be groove cutting, ± 45 ° arbitrary swing

4. Roller auxiliary support device to ensure effective support, prevent pipe sagging, and ensure processing accuracy

Cutting Samples:

|

|

Previous Page

Previous Page

Related Products

Consulting