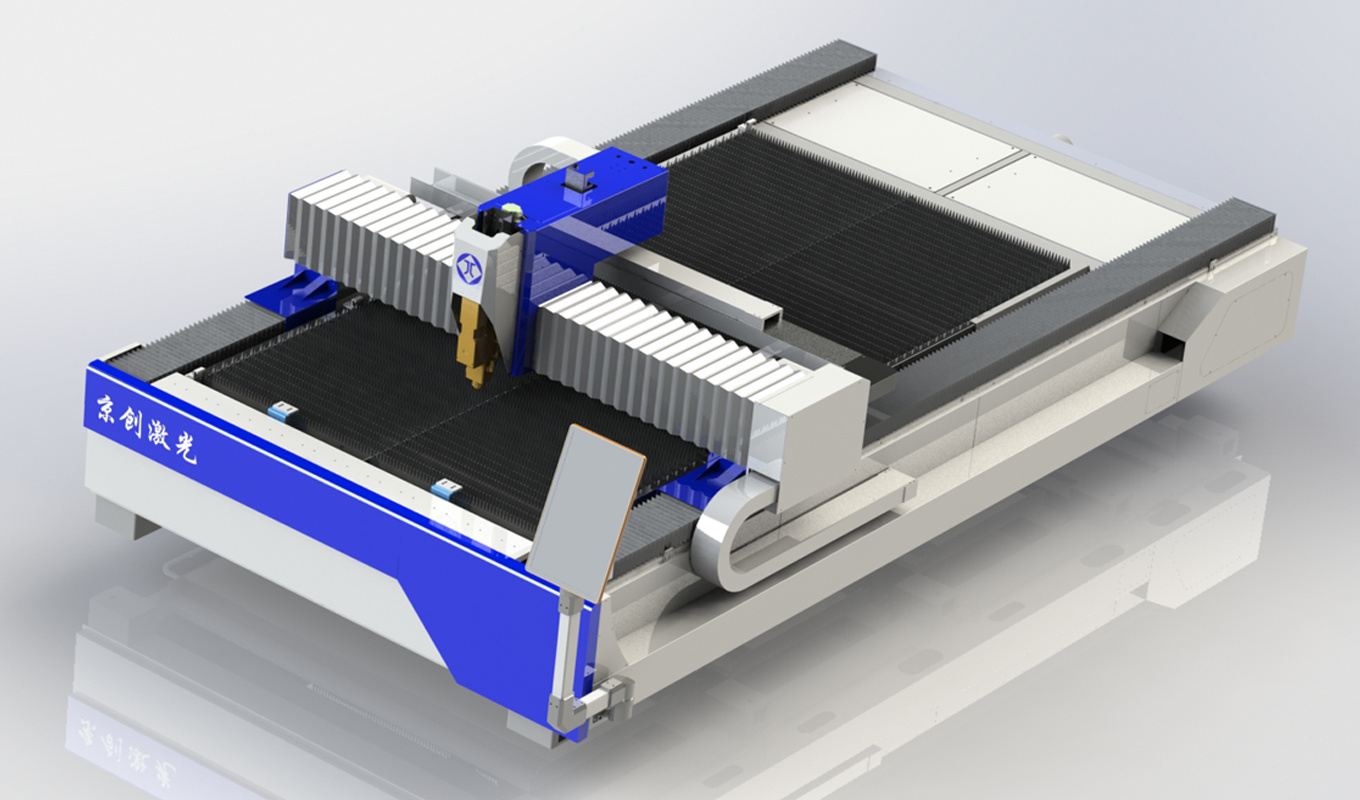

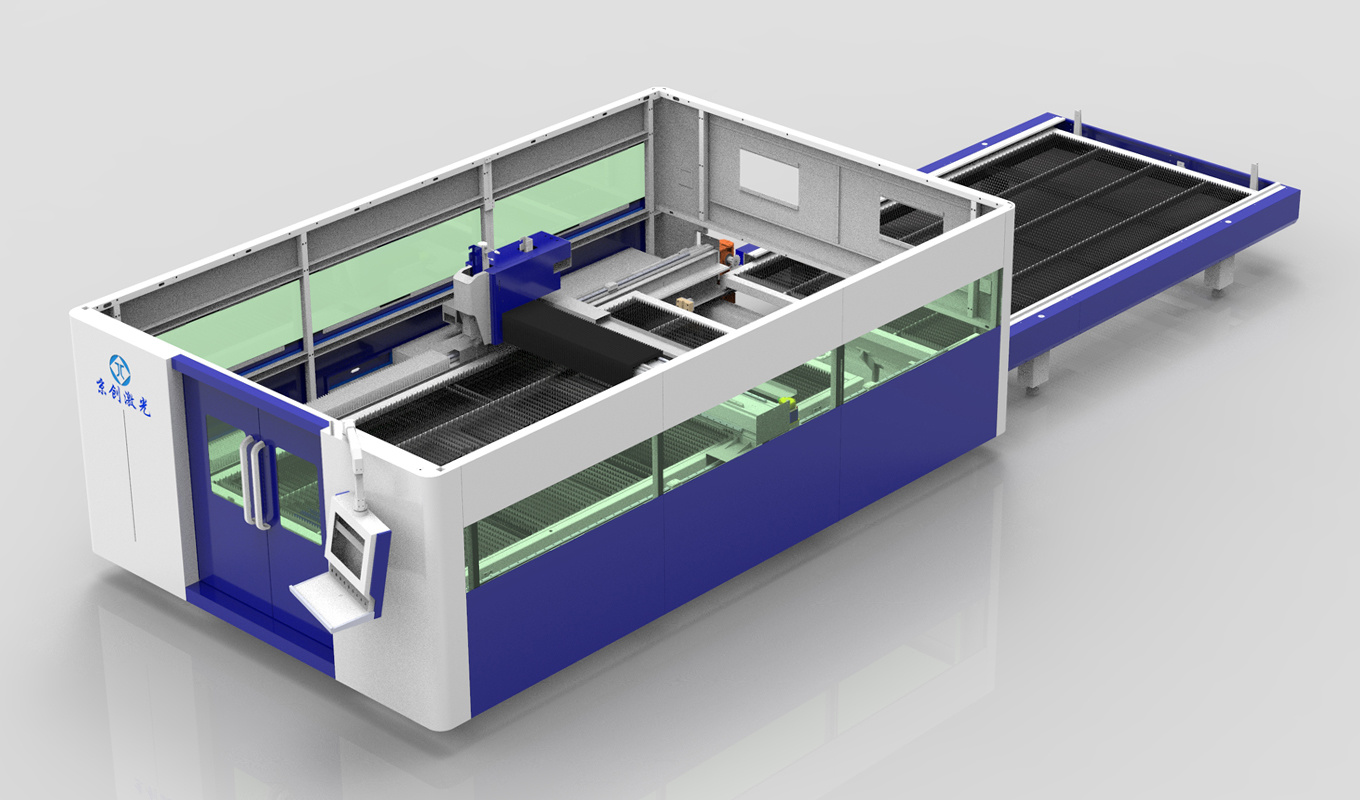

Cartridge Dust Collectors

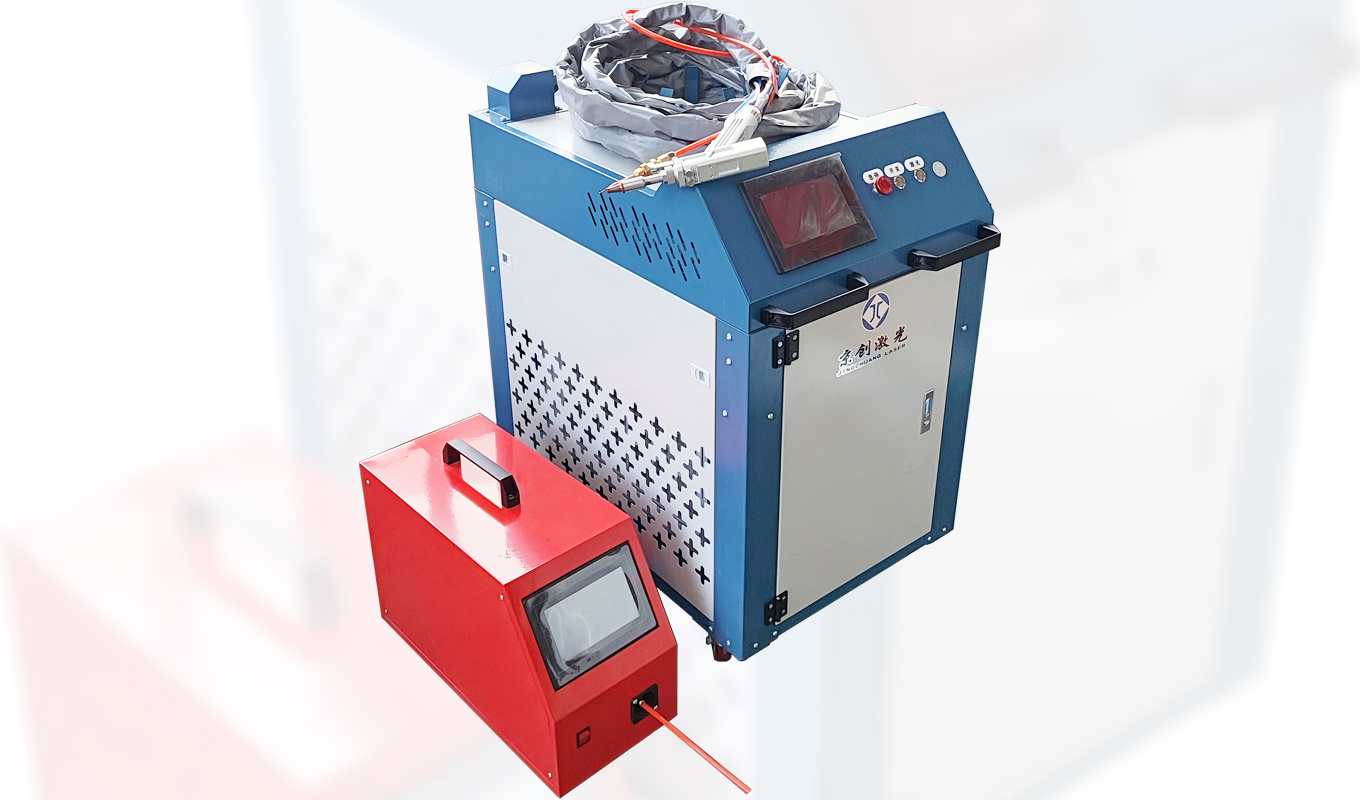

The filter drum type dust collector has the advantages of compact structure, small volume and small footprint. Can effectively remove small particles, can adapt to a variety of complex working conditions, including high temperature, high humidity, corrosive environment

Key words:

Cartridge Dust Collectors

Classification:

Cartridge Dust Collectors

Working principle

| Mould | Flame-retardant filter element | Noise reduction fan power | Processing efficiency | Body Size(meters) |

| JC-30 | 3pcs | 3000W | 3000-5000m³/h | 1.6*1.3*2.1 |

| JC-55 | 4pcs | 5500W | 4000-7500m³/h | 1.6*1.3*2.1 |

| JC-75-4 | 4pcs | 7500W | 6000-10000m³/h | 1.6*1.3*2.1 |

| JC-75-6 | 6pcs | 7500W | 6000-10000m³/h | 1.6*1.3*2.5 |

| JC-110 | 9pcs | 11kW | 8000-15000m³/h | 2*1.3*2.6 |

| JC-150 | 9pcs | 15kW | 10000-21000m³/h | 2*1.3*2.6 |

| JC-185 | 9pcs | 18.5kW | 15000-25000m³/h | 2*1.3*2.6 |

Filtration process:

After the dust-bearing gas enters the dust collector, due to the sudden expansion of the airflow section and the action of the airflow distribution plate, a part of the coarse particles settle in the ash hopper under the action of gravity and inertial forces. The dust particles with fine particle size and small density enter the dust filter chamber, and through the combined effect of Brown diffusion and screening, the dust is deposited on the surface of the filter material, and the purified gas enters the net gas chamber and is discharged by the exhaust pipe through the fan.

Cleaning process:

when the filter cylinder resistance reaches a specified value, the cleaning is usually carried out by the PLC program to control the opening and closing of the pulse valve. First of all, the chamber lifting valve is closed, the filter air is cut off, and then the electromagnetic pulse valve is opened, the compressed air is rapidly expanded in the upper box in a short time, and the filter cylinder is poured into the expansion deformation vibration, and under the action of the reverse airflow, the dust attached to the outer surface of the filter bag is stripped into the ash hopper. After the cleaning is completed, the electromagnetic pulse valve is closed, the lifting valve is opened, and the chamber is restored to the filtering state.

Previous Page

Next Page

Previous Page

Next Page

Related Products

Consulting