-

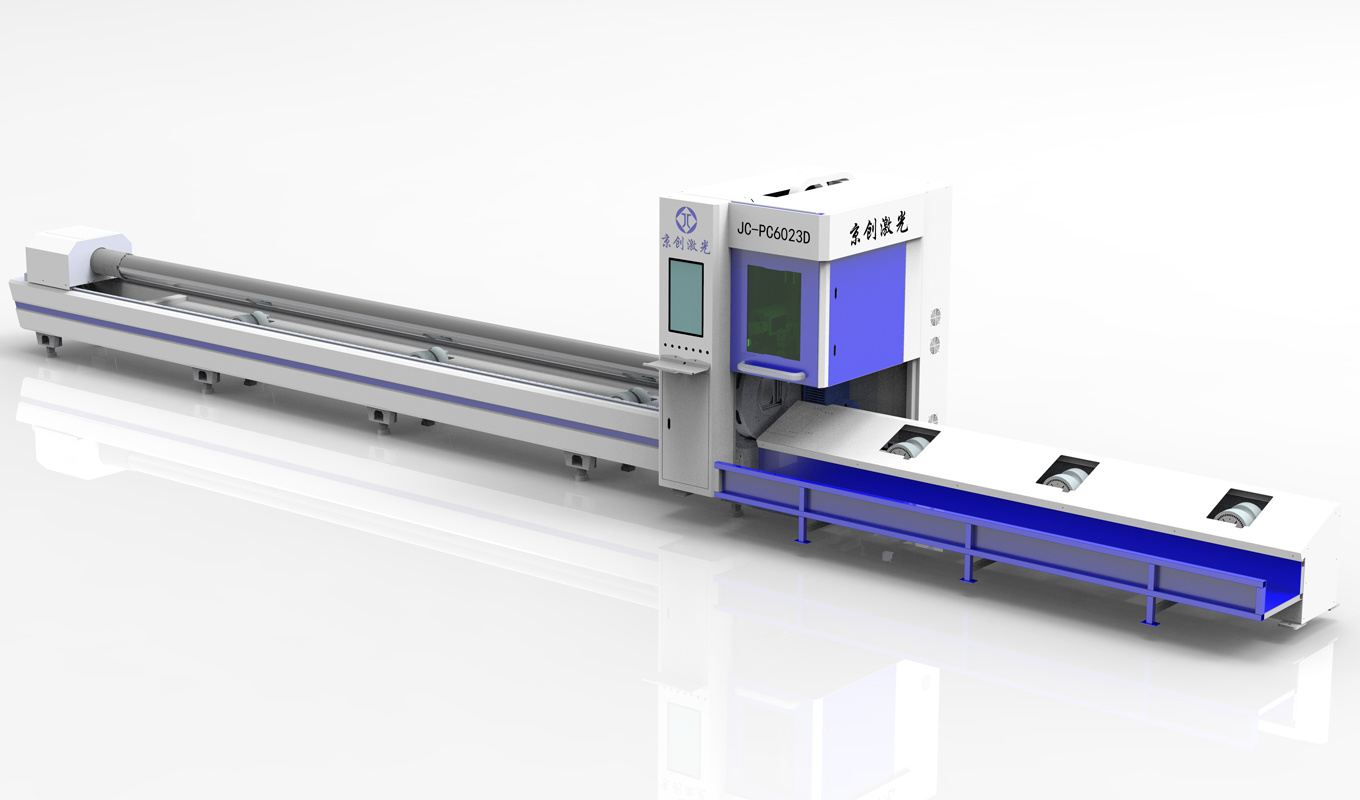

Tube Laser Cutting Machine

Cutting and Slotting any shape Iron Pipe

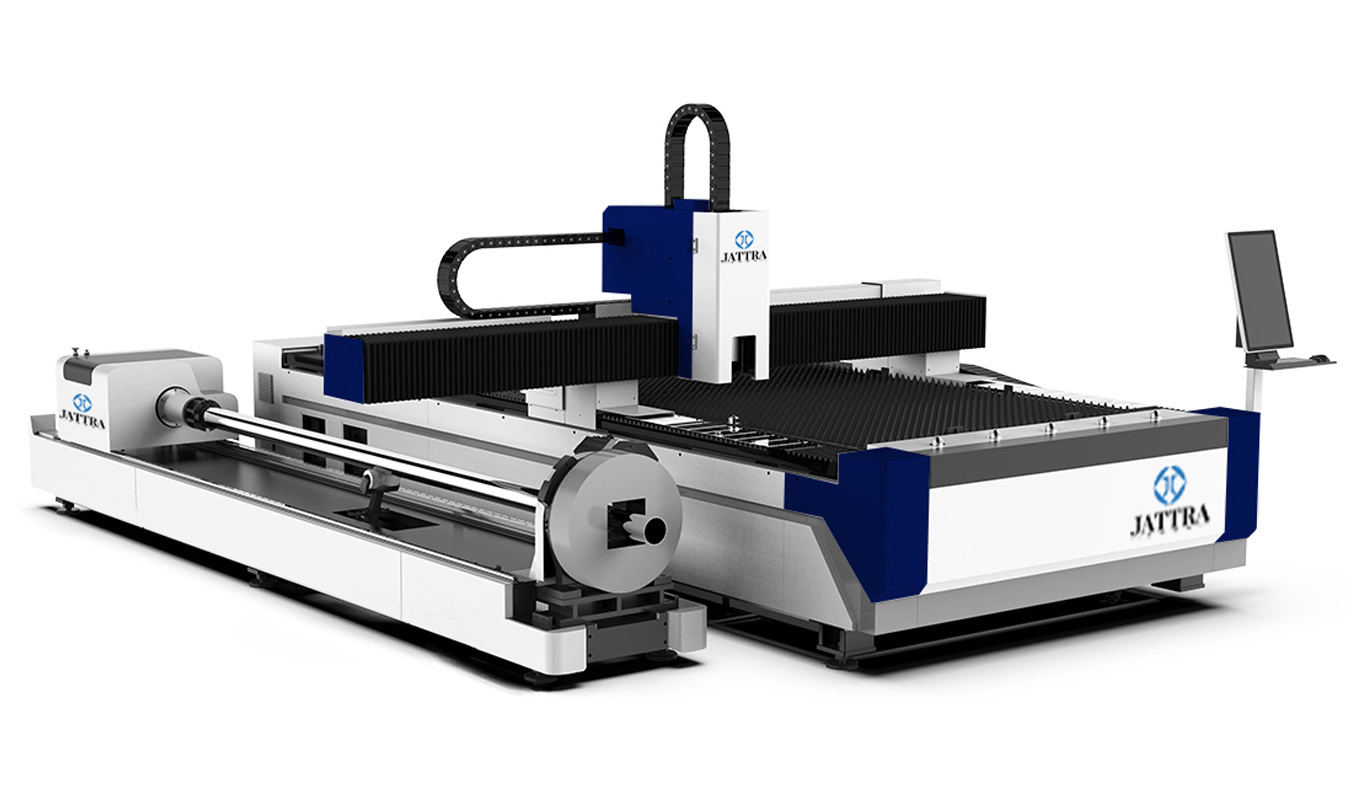

Tube and Sheet 2-in-1 laser cutter

One machine for two uses, European quality

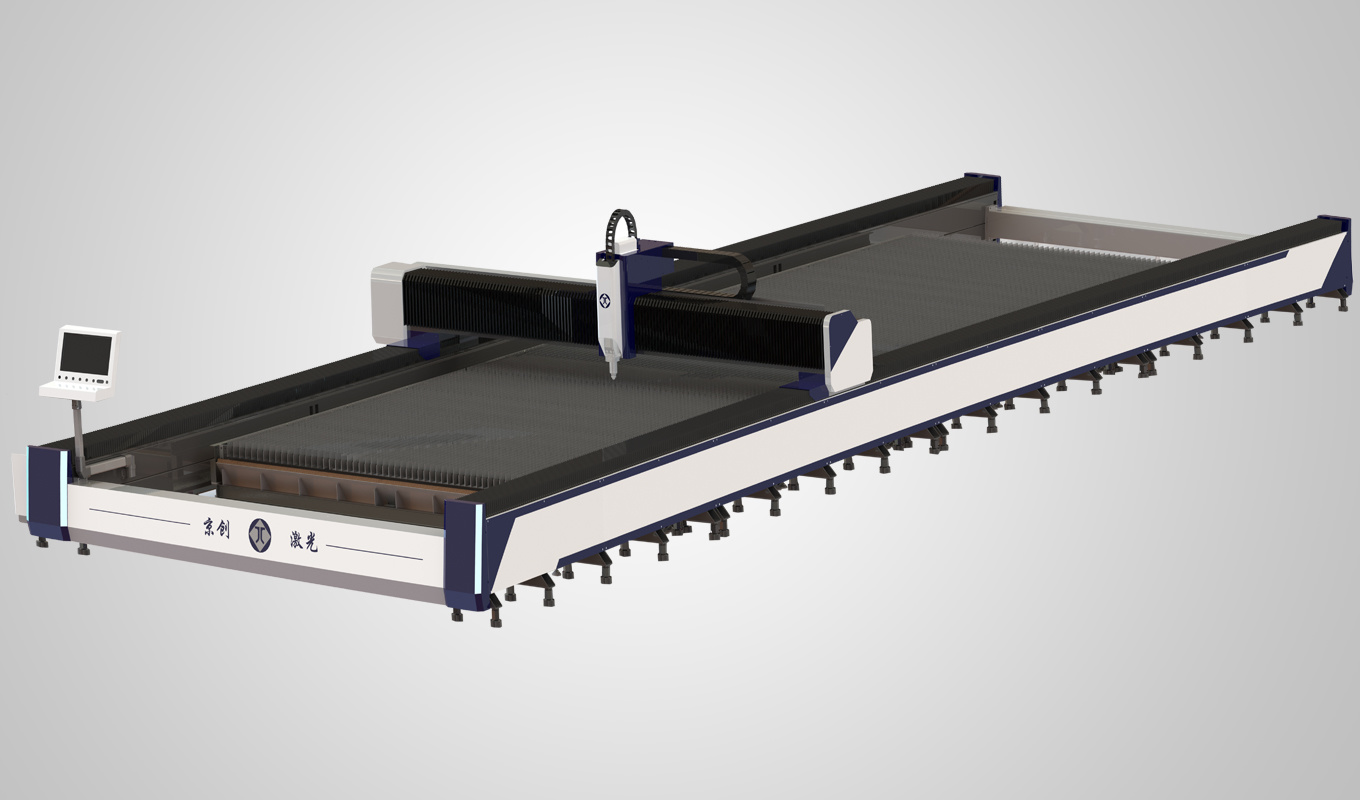

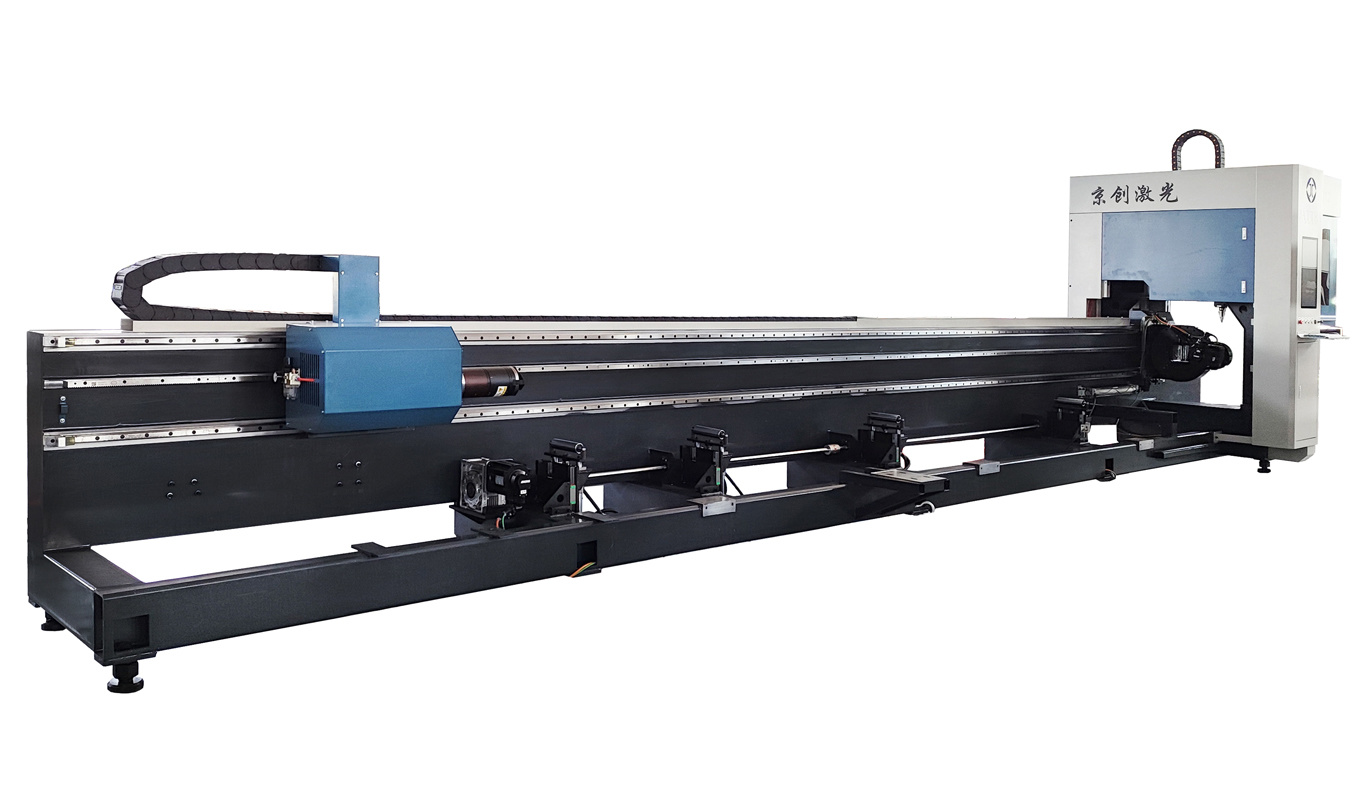

Side hanging Tube laser cutting machine

Side hanging Type tube laser cutter

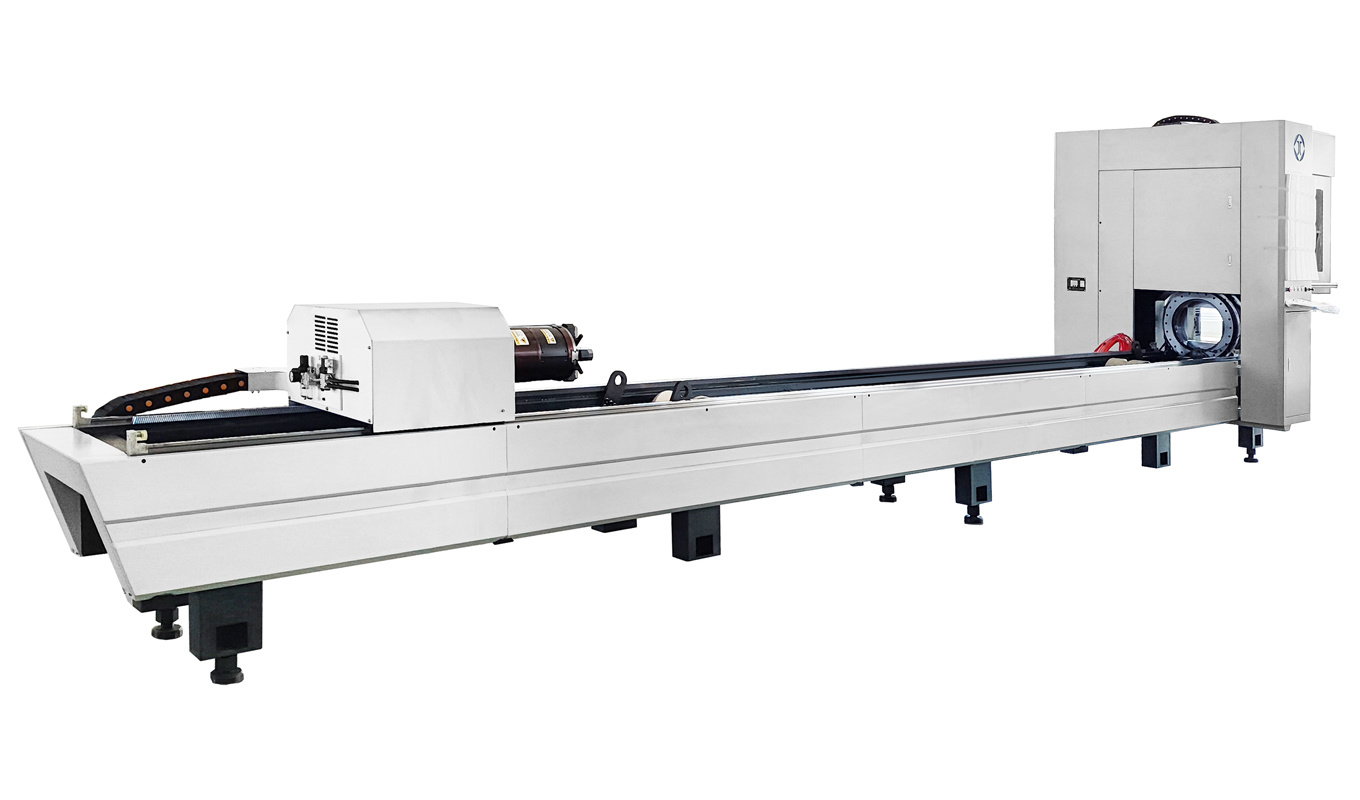

Horizontal Tube laser cutting machine

Horizontal type Tube laser cutting machine.

NEWS CENTER

JINGCHUANG LASER

15

2025

-

08

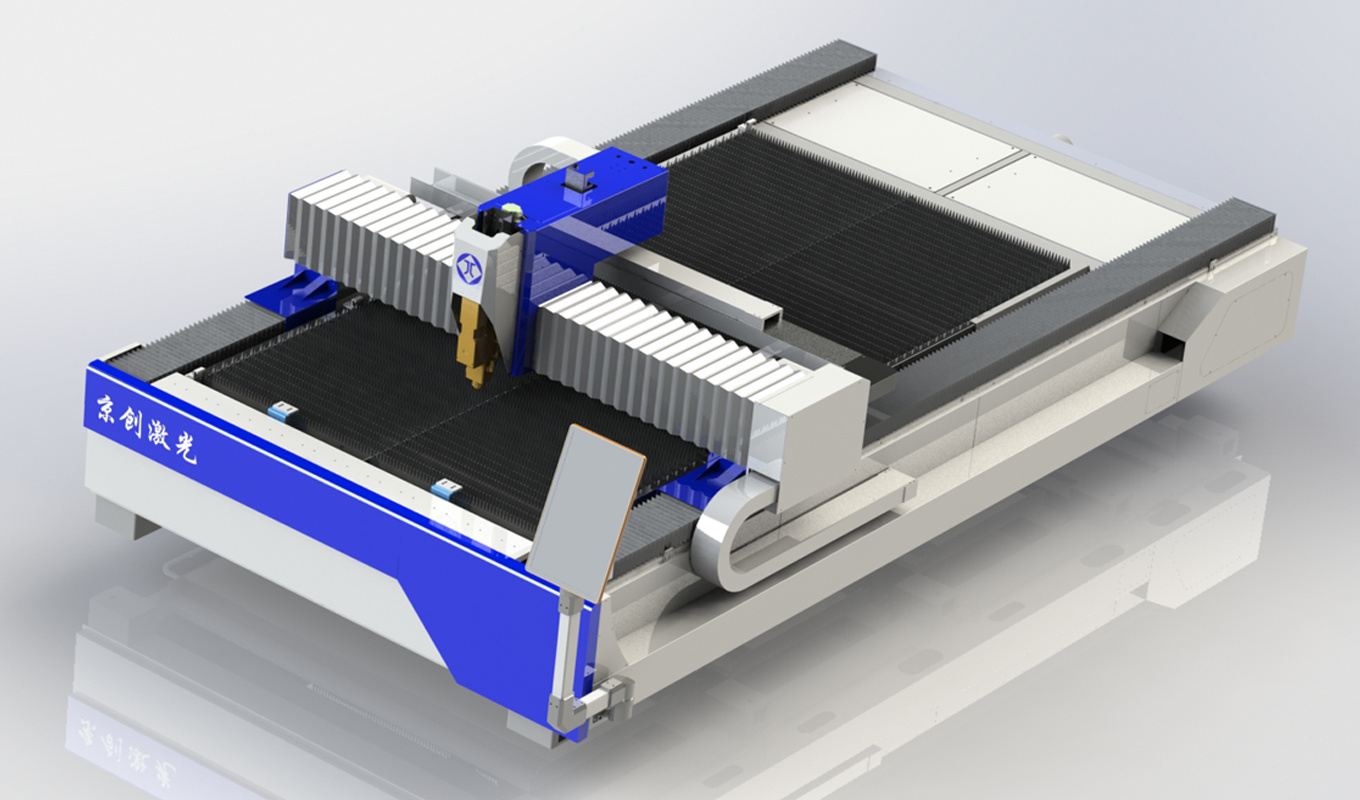

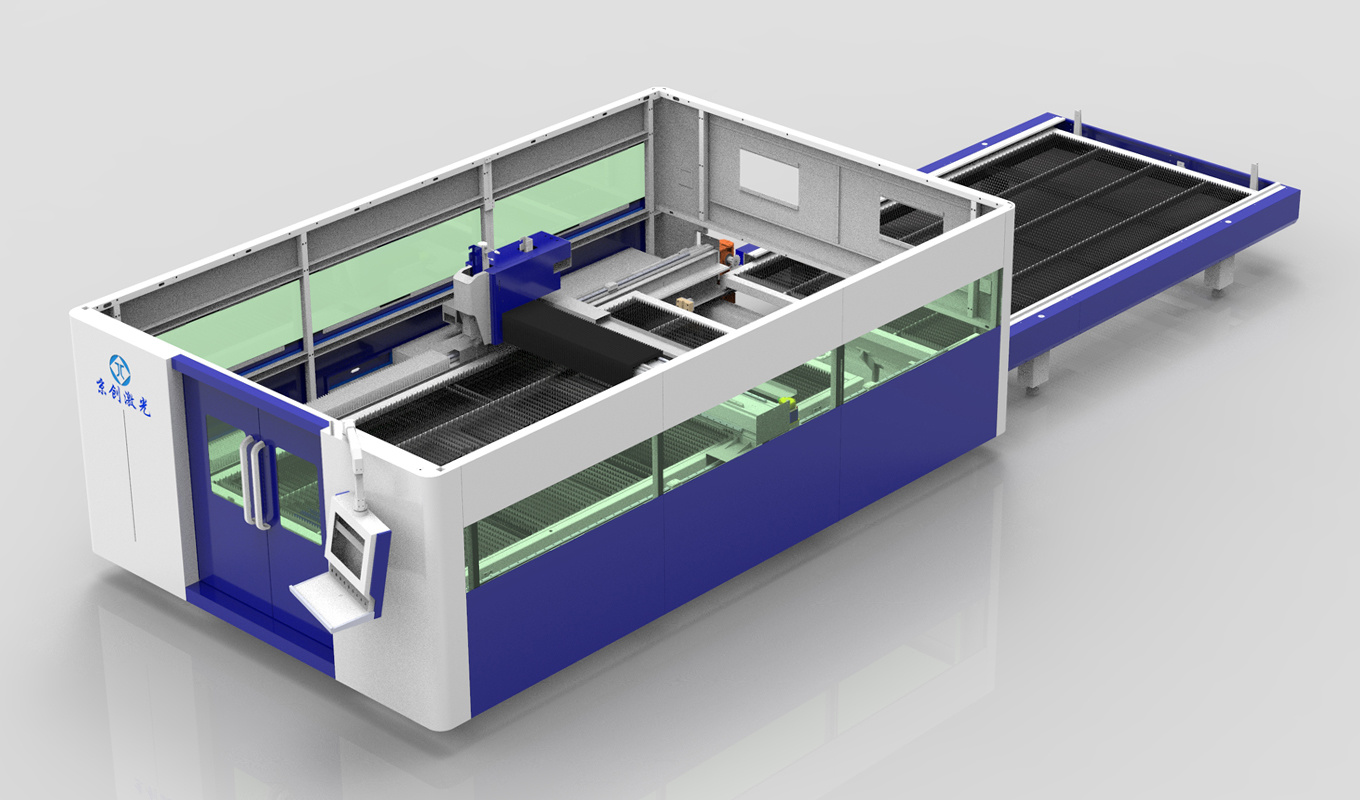

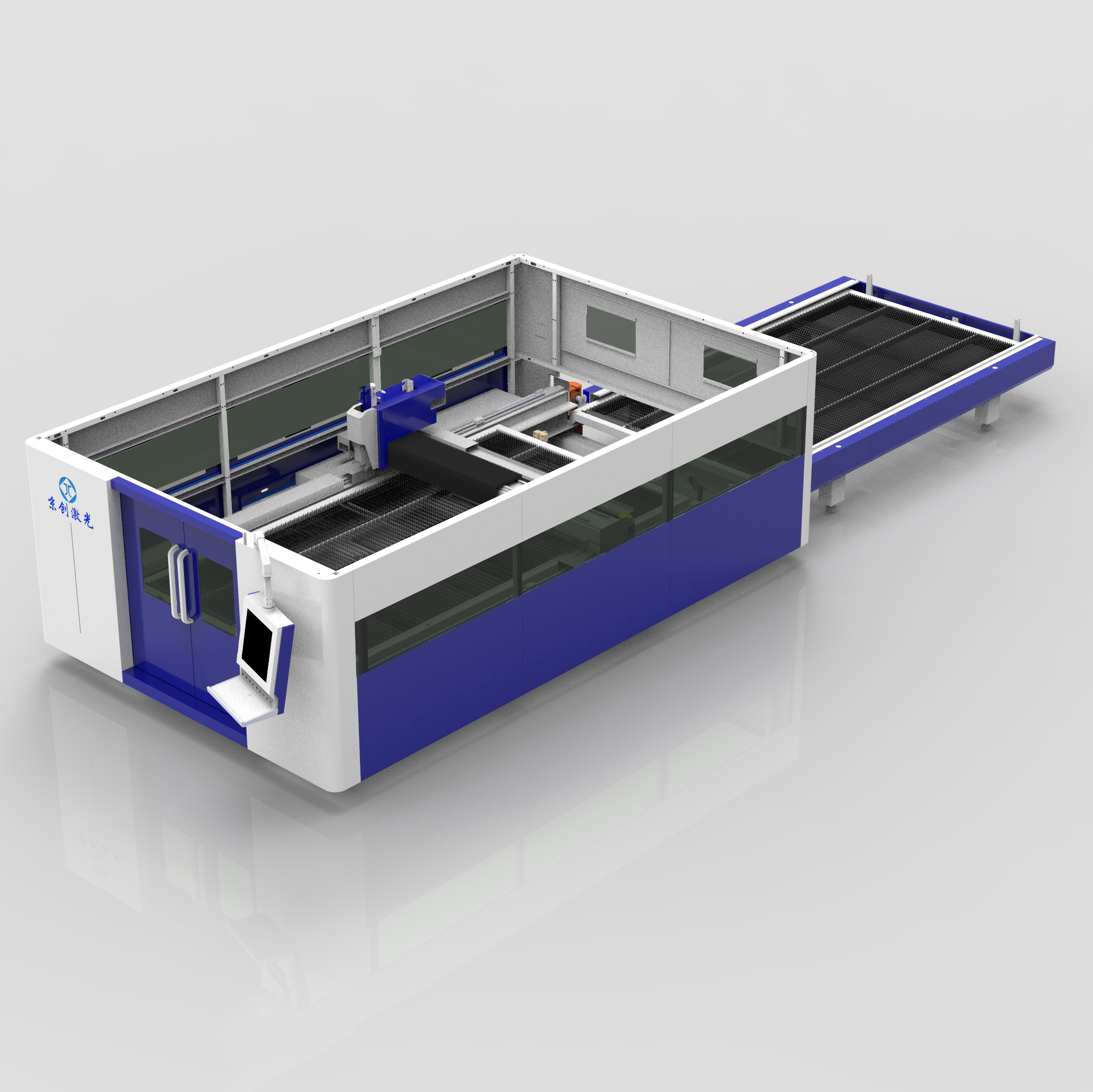

Why choose dual platform laser cutting machine

The two platform laser cutting machine uses a dual-exchange workbench design to achieve simultaneous cutting and loading, significantly improving production efficiency.

Advantages

1.High Efficiency and Time Savings: The dual-change platform allows for quick job switching (e.g., within 16 seconds), reducing downtime for loading and unloading, and providing strong continuous operation capabilities.

2.Stable Cutting Quality: The integrated welded bed and widened guide rail support surface ensure high-precision cutting and smooth cuts, making it suitable for precision parts processing.

3.Low Maintenance Costs: The fixed optical path design reduces energy loss, and fiber optic transmission eliminates the need for reflective lenses, reducing routine maintenance requirements.

4.High Safety and Environmental Performance: The fully enclosed housing and hydraulic adjustment system enhance operational safety while also being energy-efficient and environmentally friendly.

Disadvantages

1.High Initial Investment: The complex structure results in higher equipment purchase costs than single-platform models, potentially posing a barrier to entry for small and medium-sized businesses.

2.Large Footprint: The dual-platform design requires a larger installation area, which may limit space utilization in small factories.

3.Overall, this technology offers significant advantages in improving production efficiency, but there are trade-offs between cost and space considerations.

Previous Page

Previous Page

undefined

Contact Us

Tel/Wechat:

General Rong : +86 18519765888

E-mail:roger@jattragroup.com

Fax: 022-89898989

Address: No.182 Xiangyuan Road, Jingjin Science and Technology Valley Industrial Park, Wuqing District, Tianjin, China

2015-2025 Jingchuang (Tianjin) Laser Technology Co., Ltd © All Copyright

WeChat Sweep Code Us