07

2025

-

02

The difference between horizontal type and side hanging type of pipe laser cutting machine

1. Differences in structural characteristics

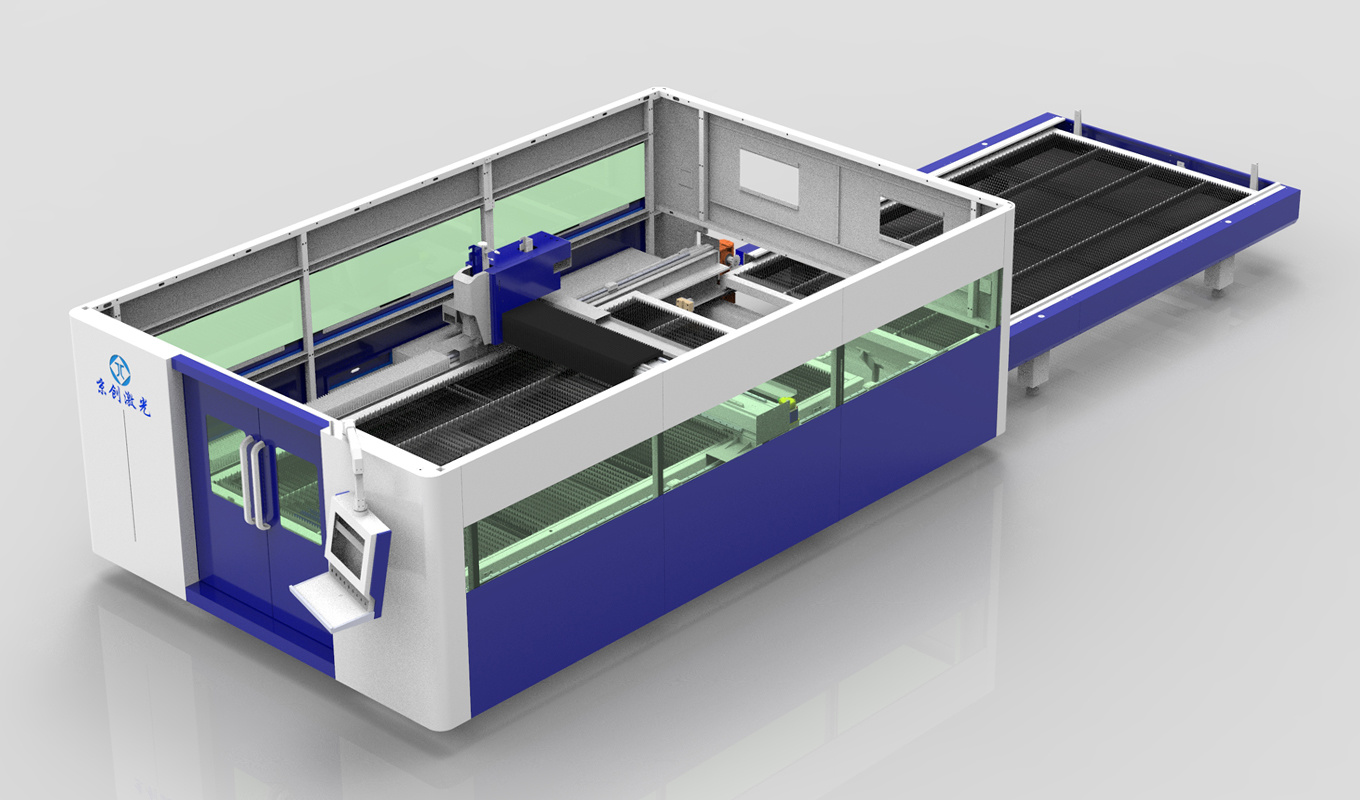

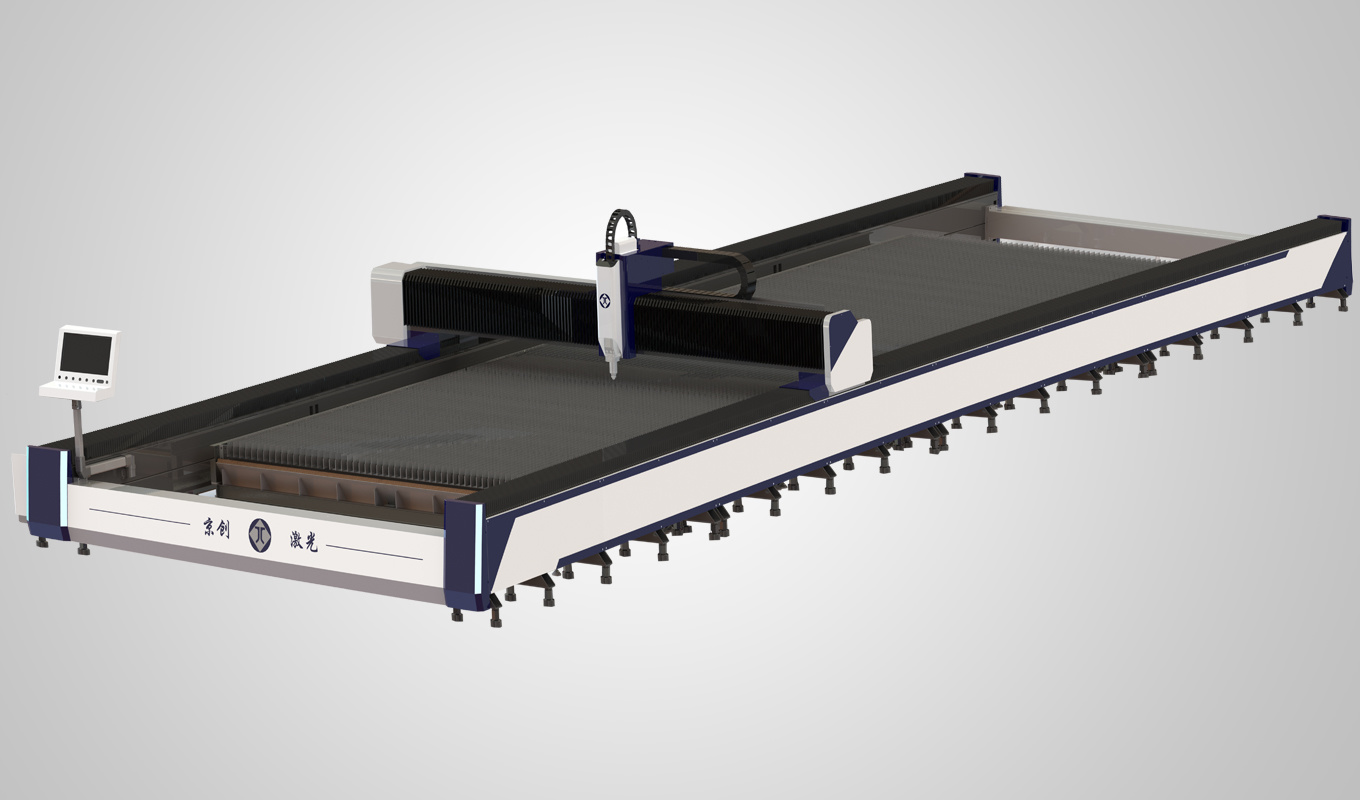

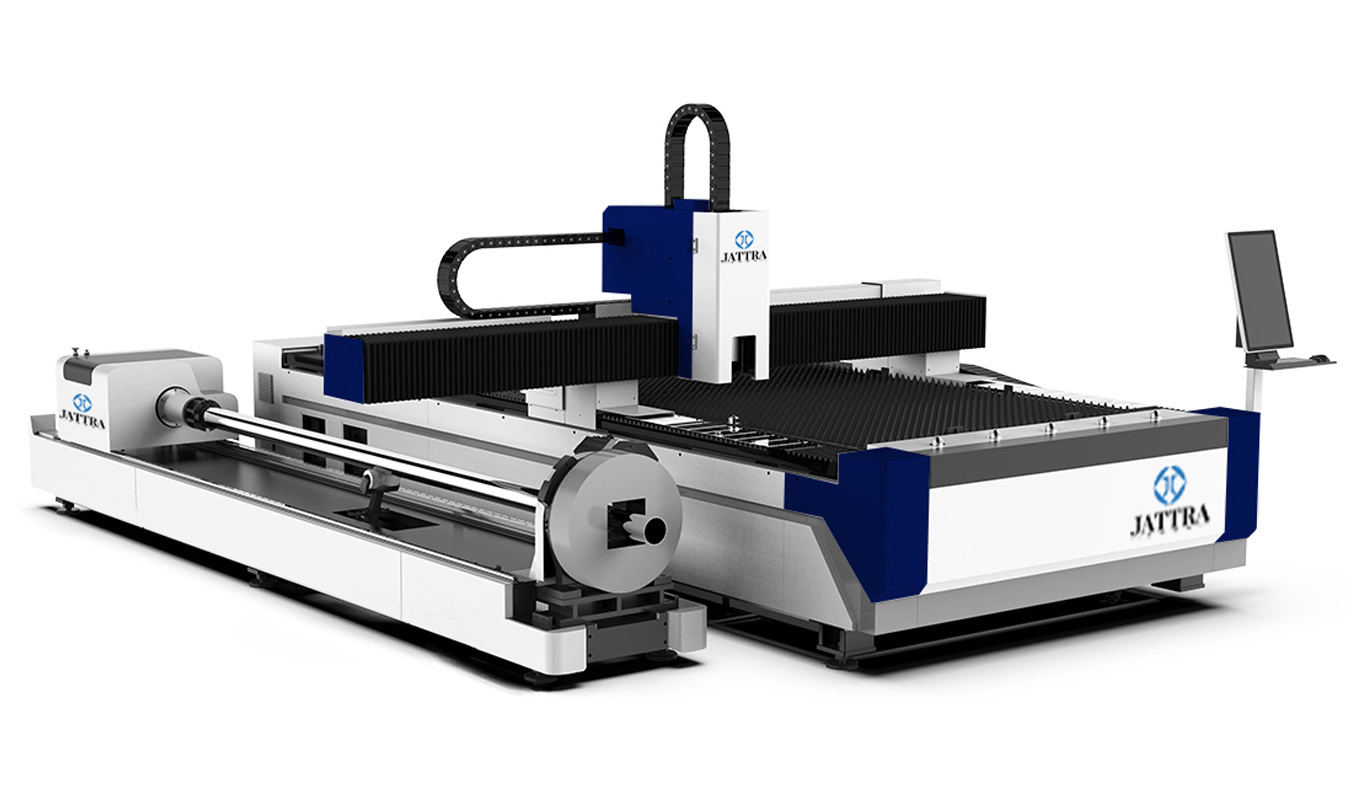

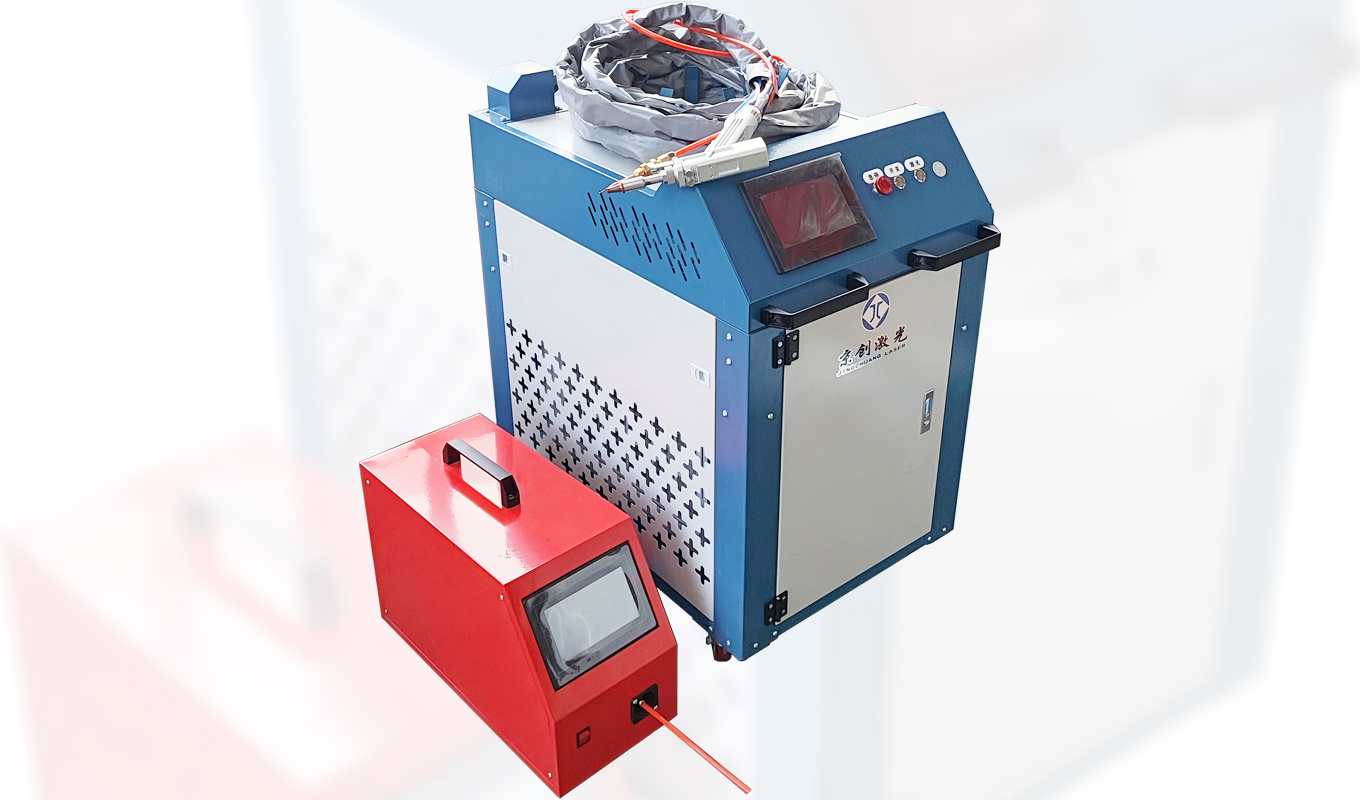

The main feature of the horizontal laser tube cutting machine is that the bed is placed horizontally, and the cutting head is moved above the bed for cutting. This structure makes the overall stability of the machine high, suitable for large pipe cutting operations. At the same time, the horizontal design is convenient for the operator to observe and adjust the cutting process to ensure the cutting accuracy.

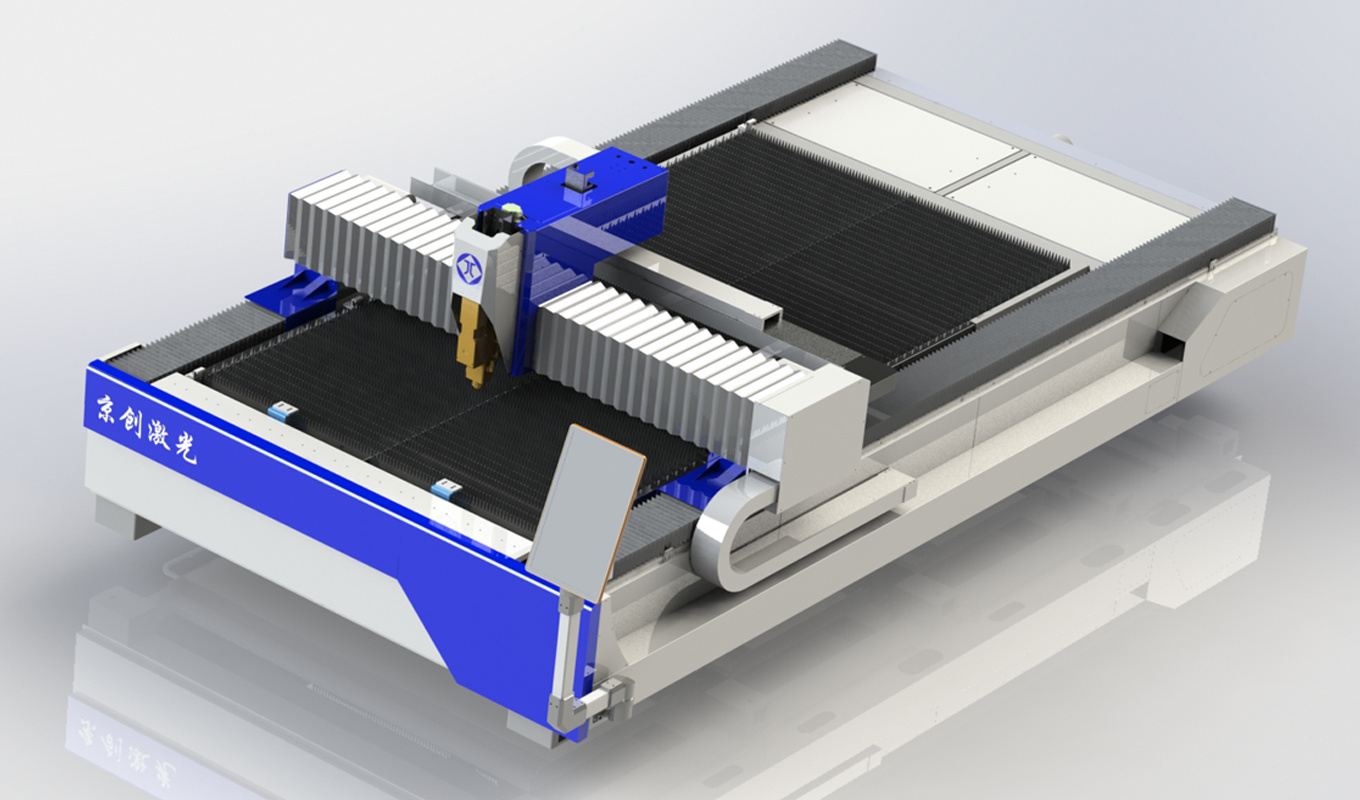

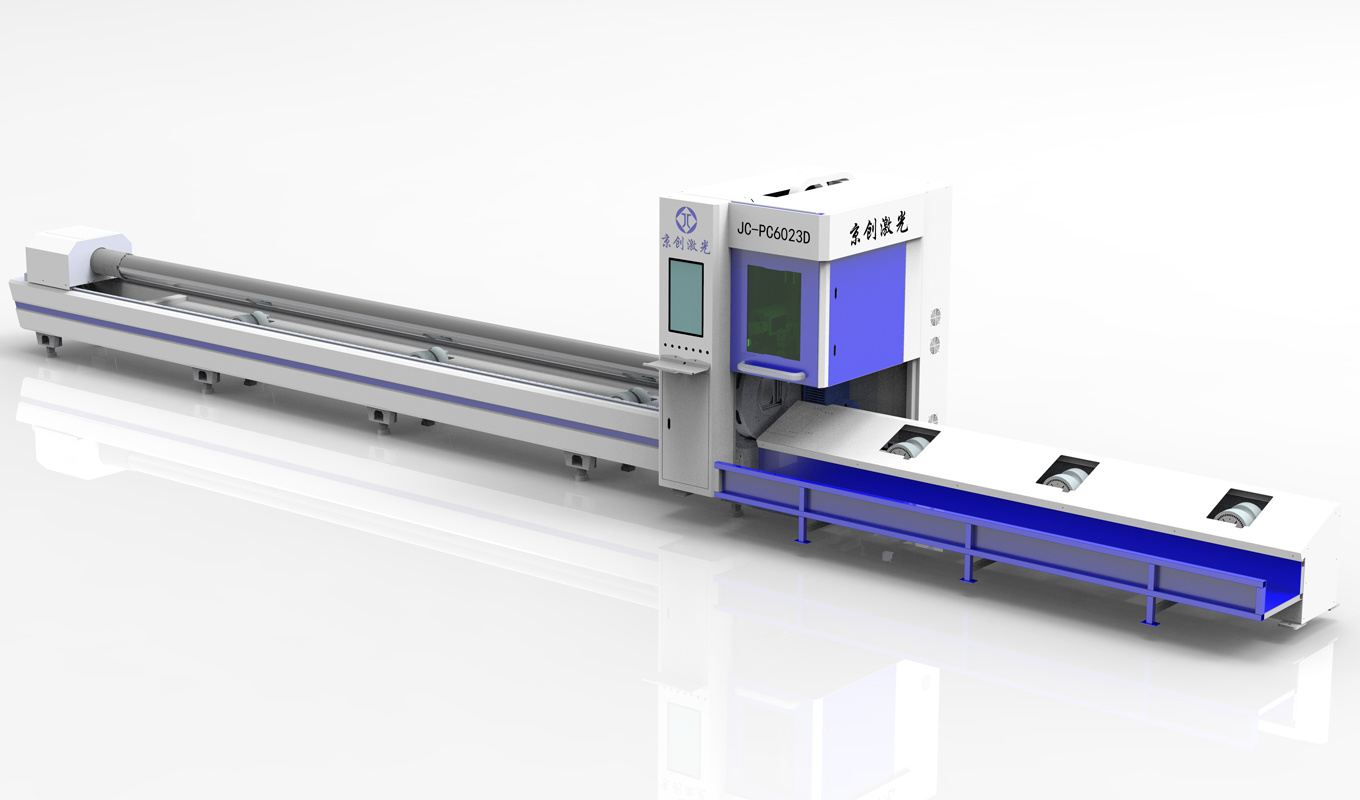

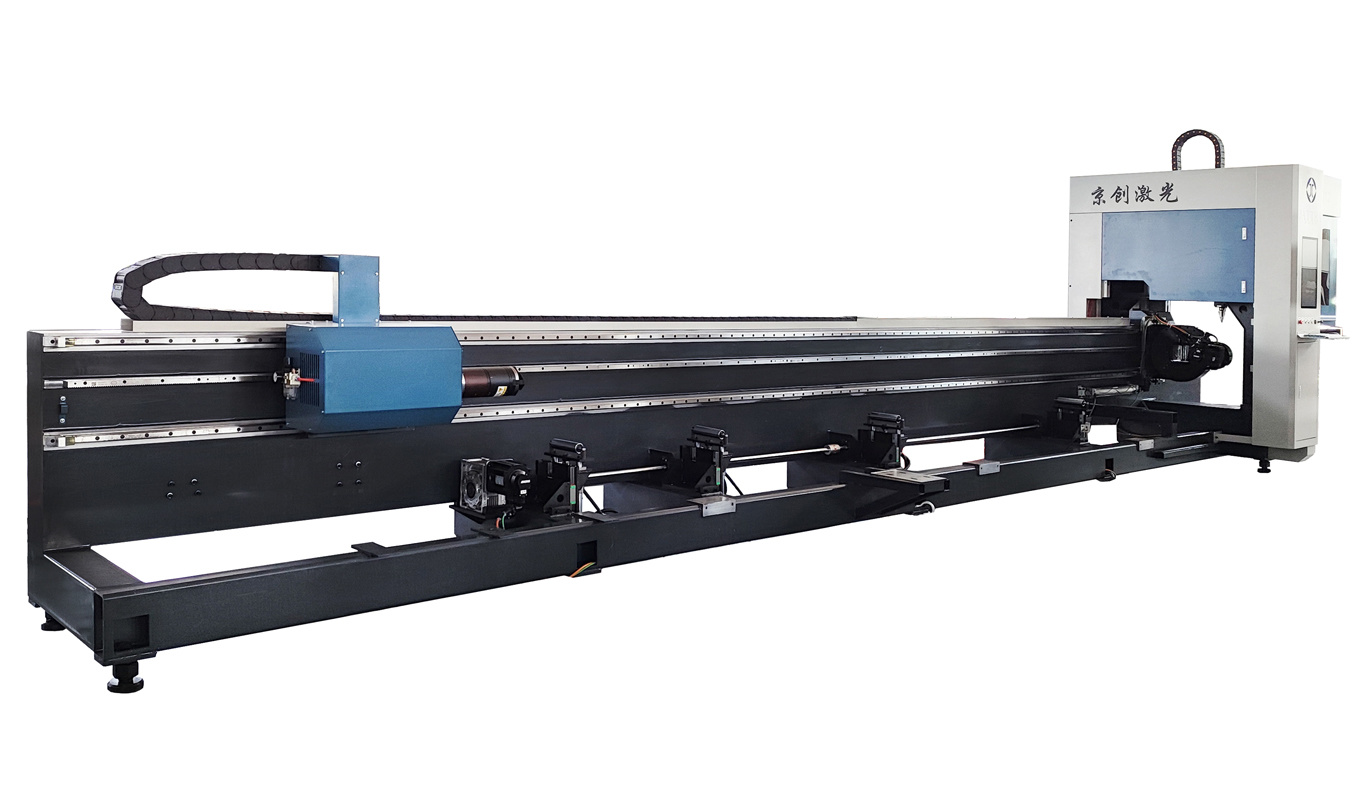

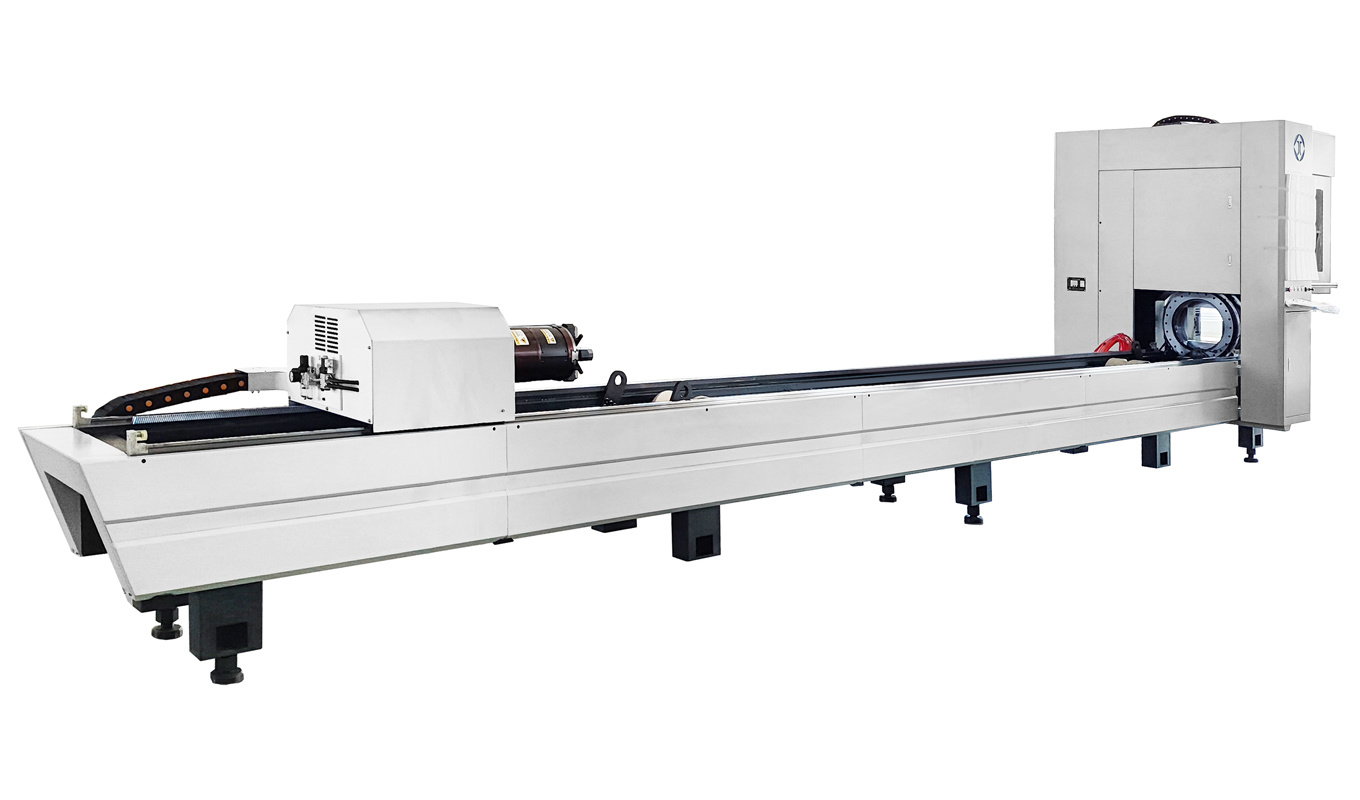

Side-hanging bed laser tube cutting machine adopts the way of side-hanging bed, and the cutting head cuts from the side. This structure is relatively compact, covers a small area, suitable for limited space workshop use. The side-hanging bed design also facilitates the loading and unloading operation of the pipe and improves the working efficiency.

↑ Picture configuration: 12 meters length,3 pieces 350mm diameter lathe chuck, side hanging type laser cutting machine with automatic unloading device.

2. Comparison of application scenarios

Because of its stability and high precision, horizontal laser pipe cutting machine is widely used in industries with high cutting requirements, such as petroleum, chemical industry, electric power and so on. In these industries, the cutting quality and precision of the pipe are directly related to the safety and service life of the product.

Side-hanging bed type laser pipe cutting machine is more suitable for small and medium-sized pipe cutting processing, especially for furniture, decoration, hardware products and other industries. Its compact structure and efficient loading and unloading operation give this type of machine a clear advantage in fast production and small batch production.

↑ Picture configuration: 6 meters length, 2 pieces 120mm diameter lathe chuck, horizontal type laser cutting machine, no unloading device.

3. Analysis of advantages and disadvantages

The advantages of horizontal laser pipe cutting machine are good stability, high precision, suitable for large pipes and high-precision cutting needs; The disadvantage is that the floor area is large, and the workshop space has certain requirements.

The advantages of the side-hanging bed laser pipe cutting machine are compact structure, small footprint, easy loading and unloading operation, suitable for rapid production; The disadvantage is that there may be certain limitations for cutting super-large pipes or pipes with special shapes.

In summary, the horizontal and side-hanging bed laser pipe cutting machine has its own characteristics and application scenarios, and the user should weigh the choice according to the actual needs.

undefined